Twój koszyk

Twój koszyk jest pusty

Aktualności firmowe

Nasze przyprawy

Nasze cukry

Nasze kapsle

-

Kegcaps 74 mm, White 86 Flatfitting A-type (700/box)

Dodaj do koszyka

Kegcaps 74 mm, White 86 Flatfitting A-type (700/box)

Dodaj do koszyka

-

Kegcaps 74 mm, Brown 154 Flatfitting A-type (700/box)

Dodaj do koszyka

Kegcaps 74 mm, Brown 154 Flatfitting A-type (700/box)

Dodaj do koszyka

-

Kegcaps 64 mm, Brown 118 Sankey S-type (EU) (1000/box)

Dodaj do koszyka

Kegcaps 64 mm, Brown 118 Sankey S-type (EU) (1000/box)

Dodaj do koszyka

-

Kegcaps 64 mm, Czerwony 150 Sankey S-type (EU) (1000/box)

Dodaj do koszyka

Kegcaps 64 mm, Czerwony 150 Sankey S-type (EU) (1000/box)

Dodaj do koszyka

-

Crown Caps 26 mm TFS-PVC Free, Dark Brown col. 2844 (10000/box)

Dodaj do koszyka

Crown Caps 26 mm TFS-PVC Free, Dark Brown col. 2844 (10000/box)

Dodaj do koszyka

Słowniczek

Mark left on side of glass by head as the beer is drunk, resembling lace.

An organic acid, which gives spoiled milk its sourness. Small amounts of pure lactic acid are commonly used as a brewing water additive, to reduce pH. Certain types of bacterial infections may produce large quantities of lactic acid during fermentation, imparting a distinct sour flavor to the finished beer. In certain styles of beer (e.g. Lambic, Berliner Weisse, Oud Bruin) some lactic sourness is a desirable characteristic.

Large class of aerobic bacteria. May be either a spoilage organism, or a consciously added fermenting agent in Kolsch, or Berliner weisse.

An organism that metabolizes lactate more readily than glucose.

A nonfermentable sugar, lactose comes from milk and has historically been added to stout, hence the style lacto-stout or milk stout.

The period of adaptation and rapid aerobic growth of yeast upon pitching to the wort. The lag time typically lasts from 2 to 12 hours.

See pilsner malt.

Brewers yeast which typically works at temperatures below 60°F, scientific classification Saccharomyces uvarum (also sometimes referred to as Saccharomyces carlsbergenesis). When used at cool temperatures, lager yeast produces the characteristically clean, crisp flavors normally associated with lager beers. Nearly all lager yeasts are bottom cropping - that is, they tend to sink to the bottom of the fermenter as fermentation draws to a close.

From the German word lagern, to store. Refers to maturation for several weeks or months at cold temperatures from 35 to 55 degrees Fahrenheit.

The process of separating spent grains from the water into which the grain's sugars have been extracted by the mashing process.

Used for the lautering process, this vessel is typically fitted with a false bottom that holds the grain bed during sparging.

The process of separating the wort from the solid part of the mash.

The Lead Conductance Value (LCV) (also known as Conductometric Value or CV) is a widely utilised measurement used to estimate of the a-acid concentration and also bittering potential of recently harvested hops. The Lead Conductance Value is measured by extracting the a-acids from the hops with methanol and then titrating a solution of lead acetate, methanol and some acetic acid into the a-acid / methanol solution. The a-acids and lead form a bright yellow lead salt precipitate that is insoluble in methanol. During the titration the conductance of the titrated solution is measured. The conductance of the solution remains relatively stable until all the a-acids are bonded with the added lead, this is the end point or lead conductance value. After the end point has been reached the lead in the solution that does not bond with a-acids causes the conductance of the solution to rise in a linear manner. If the conductance of the titration is graphed then the result is two linear lines and a small curve around the end point. The true end, and therefore true lead conductance value, can be determined by extrapolating the linear lines and finding the point at which they intercept.

Also known as "trub", lees are the deposit of yeast and sediments at the bottom of the tank after fermentation.

The amount of wort brewed each time the brew house is in operation.

French beer-promoting body. Partly responsible for launching seasonal styles in France (see also CAMRA, Craft Brewers Guild).

Typically the lightest colored (and most neutral flavored) malt extract in an extract manufacturer's product line. Can be used as a base for almost any beer style; color and flavor can be adjusted by adding small amounts of specialty malts. Some brands will also offer an "extra light" extract.

The skunky smell or flavor that results from a beer being exposed to too much direct sun or fluorescent lights. It is particularly pervasive in light beers packaged in green or clear bottles and is less common in beers packaged in brown bottles. It is caused by the reaction of hop oils to ultraviolet light.

The process used to remove foreign objects and containments from a beer line (including the keg coupler and faucet). No matter how long the line is, or how much beer is poured through the line, the line should be properly flushed, cleaned with an approved beer line cleaning chemical, and totally rinsed at least every two weeks. The best process for cleaning a beer line is one providing a turbulent action, which enables the cleaning solution to have greater impact throughout the line. Once the cleaning solution has been drained from the system, the line should be thoroughly rinsed with fresh water to ensure no chemicals remain in the line that could injure a beer drinker. Flushing the line out with beer is not considered to be a suitable rinse.

The complete set of tools and chemicals used to clean a beer system. The chemicals might include a line cleaner or sanitizer; the tools may include a faucet brush for scrubbing out the faucet, faucet wrench for removing the faucet, and instructions. The best kits contain an electric motor driven pump for circulating the cleaning solution. Other types of cleaning kits might contain a cleaning bottle or tank for holding the cleaning solution to be pumped either by hand or by gas through the beer system. The instructions for using the line cleaning chemicals should be followed carefully, as cleaners can be toxic and can cause injury or death.

A scale used to specify the diastatic power (amount of viable enzymes) present in malt. The higher the number, the more enzymes are present. If you will be mashing unmalted adjuncts with your malt, look for a base malt with a diastatic power above 100. Malts with a diastatic power below around 40 should not be counted on to have enough enzymes to convert themselves, let alone additional adjuncts.

Any of various substances that are soluble in nonpolar organic solvents, and that include fats, waxes, phosphatides, cerebrosides, and related and derived compounds. Lipids, proteins, and carbohydrates compose the principal structural components of living cells.

As alpha amylase breaks up the branched amylopectin molecules in the mash, the mash becomes less viscous and more fluid; hence the term liquefaction of the mash and alpha amylase being referred to as the liquefying enzyme.

Malt extract which has been concentrated to a syrup form. Typically contains about 20% water.

Brewer's term for hot or cold water used in the brewing process, as included in the mash or used to sparge the grains after mashing.

The vessel in which water for brewing is stored for rapid transfer to the mashing, lautering, or brewing vessels. It may store either hot or cold water.

Small water-filled device used on a carboy. See fermentation lock.

A measure of the darkness of a malt, wort and beer. Pilsener malts are in the 1 to 3 degrees Lovibond range, Munich malt from 7 to 10, Crystal Malt can be a very wide range from 15 to 100, Chocolate malt starts around 200, and really dark malts like Black Patent can be over 450.

Hops having a low alpha-acid content. Many of the preferred varieties of finishing hops are low alpha (though there are exceptions).

The fine, yellow, resinous powder on the strobile of hops.

Small bright yellow nodes at the base of each of the hop petals, which contain the resins utilized by brewers.

Top Hop - HACCP Certificate 2021-2024

Top Hop - HACCP Certificate 2021-2024

Certificate Bio Cambie Hop VOF 2024-2025

Certificate Bio Cambie Hop VOF 2024-2025

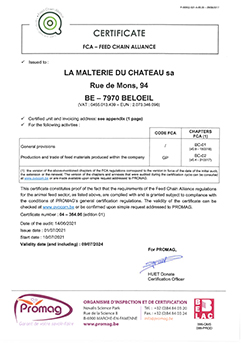

La Malterie du Chateau| FCA Malt Certificate 2022 (English) (2021-2024)

La Malterie du Chateau| FCA Malt Certificate 2022 (English) (2021-2024)

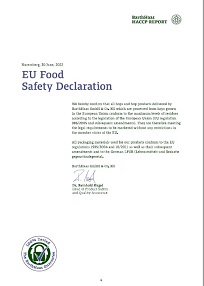

Barth Haas Hops: EU Food Safety Declaration 2022

Barth Haas Hops: EU Food Safety Declaration 2022

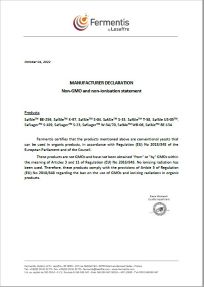

Fermentis Yeast- Non GMO declaration, non-ionisation_beer

Fermentis Yeast- Non GMO declaration, non-ionisation_beer