Twój koszyk

Twój koszyk jest pusty

Aktualności firmowe

Nasze przyprawy

Nasze cukry

Nasze kapsle

-

CC29mm TFS-PVC Free, Yellow with oxygen scav.(6500/box)

Dodaj do koszyka

CC29mm TFS-PVC Free, Yellow with oxygen scav.(6500/box)

Dodaj do koszyka

-

Kegcaps 69 mm, Złoty 116 Grundey G-type (850/box)

Dodaj do koszyka

Kegcaps 69 mm, Złoty 116 Grundey G-type (850/box)

Dodaj do koszyka

-

Kegcaps 64 mm, Czerwony 102 Sankey S-type (EU) (1000/box)

Dodaj do koszyka

Kegcaps 64 mm, Czerwony 102 Sankey S-type (EU) (1000/box)

Dodaj do koszyka

-

Kapsle 26mm TFS-PVC Free, Cyan Opaque col. 2616 (10000/box)

Dodaj do koszyka

Kapsle 26mm TFS-PVC Free, Cyan Opaque col. 2616 (10000/box)

Dodaj do koszyka

-

Kapsle 26mm TFS-PVC Free, Red Neu col. 2151 (10000/box)

Dodaj do koszyka

Kapsle 26mm TFS-PVC Free, Red Neu col. 2151 (10000/box)

Dodaj do koszyka

Słowniczek

Aroma and flavor due to long lag times and wort spoilage bacteria that arise from contamination. Also known as cooked vegetable-like flavor.

Chemical compound with the formula CaCO3, a.k.a. chalk. Tends to raise pH; food grade calcium carbonate may be added in small amounts to brewing water if the pH is too low.

Chemical compound with the formula CaSO4, a.k.a. gypsum. Tends to lower mash pH; food grade calcium sulfate may be added in small amounts to brewing water if the pH is too high. Tends to accentuate hop bitterness; frequently added to brewing water for English-style Pale Ales, in an attempt to mimic the brewing water of Burton-On-Trent.

A style of beer which supposedly originated on the west coast of the US, in the 1800s. Superficially similar to a Pale Ale, but with a unique character from the use of lager yeast at elevated (60s) temperatures. Also called "Steam Beer" (but the only commercial brewery which can use the name "Steam Beer" is Anchor, because they have trademarked it.)

Pellets of sodium metabisulphite used as infection-inhibiting agent. Not technically a sterilizer. Used more in wine, mead, and cider making than brewing.

The Campaign for Real Ale, the British-based grassroots organization formed to educate, lobby and protect traditional cask-conditioned ale from becoming extinct.

Candy sugar is made by superheating and then cooling a highly concentrated sugar solution. Pale candy syrup is much darker than sucrose or invert sugar syrup. Belgian brewers prefer to use candy sugar, in either solid or syrup form, because it contributes to good head retention in a high-gravity, lightly hopped beer.

Sucrose, or white table sugar is a highly fermentable sugar, usually refined from sugar cane or sugar beets. In brewing, cane sugar is sometimes used as an adjunct because it is cheaper than malt. It lightens the color and body of the beer, boosts the alcohol content, and can add a cidery taste that is considered not true beer flavor.

See Classic American Pilsener.

A dark caramel malt, made by DWC (Belgium). Color typically runs around 60 L. May be mashed or steeped.

An extremely light caramel malt. Color typically runs around 6 L. May be mashed or steeped.

A medium caramel malt, made by DWC (Belgium). Color typically runs around 20°L. May be mashed or steeped.

Complex organic compounds that form the majority of the barley malt. Carbohydrates include insoluble cellulose, soluble hemicellulose, starch and sugars.

See carbon dioxide.

Alkaline salts whose anions are derived from carbonic acid.

A ball lock quick-disconnect keg fitting which screws onto the top of a plastic soda bottle. Allows beer (or any beverage, for that matter) to be force carbonated in a soda bottle, by attaching it to a CO2 tank.

A glass or plastic container that looks like an office water-cooler bottle or a large jug. It is used by homebrewers for fermenting the beer.

A rubber cap (usually orange in color) which snaps over the mouth of a glass carboy. Has two holes, which can be covered with caps. Can be used to seal a glass carboy during closed fermentation (the center hole can be fitted with an airlock), or during racking (a plastic racking cane will fit through the center hole).

The heat-induced browning of sugars, different from the Maillard reactions in malt kilning.

Another name for Irish moss.

See cask conditioning. - It is usually poured via gravity or a hand pump, not via CO2. It may seem flat compared to "regular" beers. The beer is also called living beer as the yeast is still active in the brew.

Instead of being filtered and stored in pressurized kegs, cask-conditioned beer is kept in a cask with its yeast and is dispensed using a special hand pump called a beer engine. This method is popular in England. Cask conditioned beer only stays good for about 3 months, unlike bottle conditioned beer.

Electro-positive ion.

The smallest structural unit of living organisms that is able to grow and reproduce independently.

Growth of cells under laboratory conditions.

Similar to a starch, but organized in a mirror aspect; cellulose cannot be broken down by starch enzymes.

Name of originator of the centigrade scale.

A clarification method using centrifugal force to strain and clarify the wort during its cooling stage and the finished beer prior to racking.

(Cer-a-vehs-a-file) 1.an aficionado of beers and ales, 2.a devotee to the decoction of barley infused with hops and fermented, 3.an imbiber of beer on the highest order, bordering on devotion, 4.one who pursues the very finest in malted beverages.

Broad term for a group of grass plant species cultivated as food grains, where as barley is one.

These are typically for Belgian abbey and trappist style beer. They can have a look of royalty about them. They can be more "V" shaped with either straight or an inward curving top, sometimes rimmed with a precious metal. The stem is thick and the length is usually rather short.

See calcium carbonate.

A term used to describe the amount of malt used in a brew.

A one-way valve, commonly used on the gas outlet of a CO2 regulator to prevent beer from flowing back into the regulator and damaging it.

By adding certain clarifiers to beer, it prevents chill haze by precipitating out the haze causing agents.

This is one of the several tricks that German brewers use to circumvent the limitations of the Reinheitsgebot (German Purity Decree). Under the Reinheitsgebot, only water, hops, malt and yeast may be used as beer ingredients. However, unmalted barley can often produce favourable flavours and properties in beer. So maltsters sometimes begin to malt their barley, but then halt the process almost immediately so that only 1/4 of the grain is modified. The Reinheitsgebot does allow the use of this grain, since technically speaking it has been malted. By these means German brewers can take advantage of some of the desirable properties of unmalted grain, since 3/4 of the husk was not modified by the short malting period.

A chemical compound containing chlorine, commonly used by municipal water treatment facilities to kill microorganisms in the tap water. If your tap water contains chloramine, you should remove it (by filtering through activated charcoal) before using the water for brewing.

An ion that imparts a sweet finish to beer.

A highly toxic, extremely reactive gas, chemical symbol Cl. In the form of hypochlorite or chloramine, commonly used by municipal water treatment facilities, to kill microorganisms in drinking water. Bleach (hypochlorite) is also commonly used as an equipment cleaner/sanitizer in homebrewing.

Family of chemical compounds, which are formed when chlorine combines with organic compounds called phenols. Typically have a medicinal or plastic-like taste. Chlorinated tap water, or over-use (or inadequate rinsing) of bleach as a sanitizing agent can lead to objectionable levels of chlorophenols in beer.

Malted barley that has been roasted to a deep brown color. It gives a nutty, toasted flavor to beers as well as deep reddish brown color.

A vat in which brewers' grain is soaked.

Commonly referred to as a fining. Any ingredient added in minimal quantities during the production process to improve the clarity of beer. Examples include Irish Moss and Isinglass.

The ancestor of the American Light Lager style, as it existed prior to Prohibition. More flavor and body than an American Light Lager -- closer to its Continental Pilsner roots, but with an American malt and hop character. Frequently contains corn as an adjunct.

Separation of spent grain from wort.

The practice of fermenting beer in a closed fermenter, where the CO2 produced during fermentation is allowed to escape, but outside air is prevented from contacting the fermenting wort. Closed fermentation is the method most commonly used by homebrewers in the US. Some traditional British and Belgian breweries (and a few American micros as well) use open fermentation, where the fermenters are open to the air.

A beer that is overly sweet to the point of being unpleasant.

A tank used to hold CO2 in liquid form. Usually made from steel or aluminum. The cylinders come in a variety of sizes ranging from 2.5 lbs to 50 lbs. The cylinder should be secured at all times, and installed in an up right position. Laying the cylinder on its side while connected to the regulator could damage the regulator. Whether the cylinder is small or large, the internal pressure of the unit is approximately 800 lbs at room temperature, and so the cylinder should not be allowed to roll around or stand freely. Caution - Damage to a cylinder valve or cylinder may result in a serious injury or death. In the event the CO2 is released into the room, the room should be vented to allow fresh air to enter.

A term used by Brewers to measure the amount of CO 2 (Carbon Dioxide) dissolved into each beer. In a Brewer's recipe, there is a specification for the CO2 volumes. The CO2 volume in a beer determines the amount of CO2 that needs to be applied to the keg in order to maintain the characteristics of the beer.

Proteins that coagulate and fall out of solution when the wort is rapidly cooled prior to pitching the yeast.

An alternative to pasteurizing beer. In this process the beer is passed through a very fine filter that removes the yeast and halts the fermentation process.

Water-borne bacteria, often associated with pollution.

Any of several cone-like flower or fruit clusters, as in the hop.

Generic term used to refer to various variations on the Pilsner style of beer, brewed in Europe.

Beer made by one brewery and then marketed by a company calling itself a brewery. The latter uses the brewing facilities of the former.

A company that markets, sells, and owns all rights to a beer brand but outsources the production of the beer to another brewery. Confusingly, breweries that offer these production services are also commonly referred to as contract breweries.

The enzymatic transformation of starches into various fermentable and unfermentable sugars that occurs during the mashing process.

Aroma and flavor due to long lag times and wort spoilage bacteria that arise from contamination. Also known as cabbage-like flavor.

As the wort cools in contracts (or shrinks). The same mass will take up less volume. This is the percentage that the wort will shrink from cooling.

Craftsperson who hand-builds beer kegs from wood.

Any vessel used to serve beer, including kegs, firkins, pins, etc.

See brew kettle.

See kettle finings.

A cereal grain commonly used as an adjuct in American Light Lagers, and Classic American Pilsners. Also used in some British ales.

Dextrose which has been manufactured using corn as the raw material.

A sugar syrup which have been manufactured from corn. May contain flavorings (e.g. vanilla), and/or preservatives.

A tall, skinny stainless steel keg, typically 5 gallons in capacity, manufactured by the Cornelius company. Probably the most popular system for kegging homebrew.

An inexpensive grain mill (of the plate mill type), which can be converted for brewing use. While it has a reputation for being somewhat difficult to adjust, and may cause a bit more husk shredding that a roller mill, it is a reasonable choice for an all-grain homebrewer on a budget.

A heap of steeped barley that is cast on the malting floor for germination.

A type of wort chiller which consists of a narrow metal tube running through the inside of a larger (typically plastic) tube. Hot wort flows through the inner tube, while cold water flows through the outer tube, in the opposite direction. More efficient than an immersion chiller, but more difficult to clean and sanitize.

An American craft brewer is small, independent and traditional. Craft beer comes only from a craft brewer. Small = annual production of beer less than 2 million barrels. Beer production is attributed to a brewer according to the rules of alternating proprietorships. FMB's are not considered beer for purposes of this definition. Independent = Less than 25% of the craft brewery is owned or controlled (or equivalent economic interest) by an alcoholic beverage industry member who is not themselves a craft brewer. Traditional = A brewer who has either an all malt flagship (the beer which represents the greatest volume among that brewers brands) or has at least 50% of its volume in either all malt beers or in beers which use adjuncts to enhance rather than lighten flavor.

A metal cap with a cork or plastic lining and a crown-shaped contour (skirt) which is crimped around the mouth of a bottle to form an airtight seal that retains carbon dioxide gas.

A procedure used to break grain into small pieces while maintaining the integrity of the barley husk.

When fresh malt is carefully dried at warm temperatures, some of the starches are converted to sugars which crystallize within the grains. When these crystal malts are used in brewing, they add sweetness, body and a reddish gold color to the beer.

The last step in floor malting, when the grain is heated to fully develop flavor and color.

Abbreviation for hundredweight. An English unit of weight equal to 112 pounds.

Referring to cell or cell plasm.

Hops Hopfenveredlung St.Johann, Certificate ISO 14001:2015 2022-2025

Hops Hopfenveredlung St.Johann, Certificate ISO 14001:2015 2022-2025

Belgosuc sugar, Management System Certificate 2022 (English)

Belgosuc sugar, Management System Certificate 2022 (English)

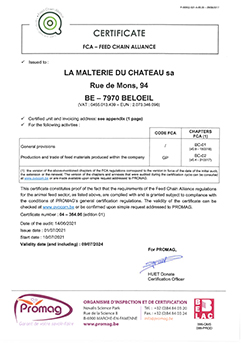

La Malterie du Chateau| FCA Malt Certificate 2022 (English) (2021-2024)

La Malterie du Chateau| FCA Malt Certificate 2022 (English) (2021-2024)

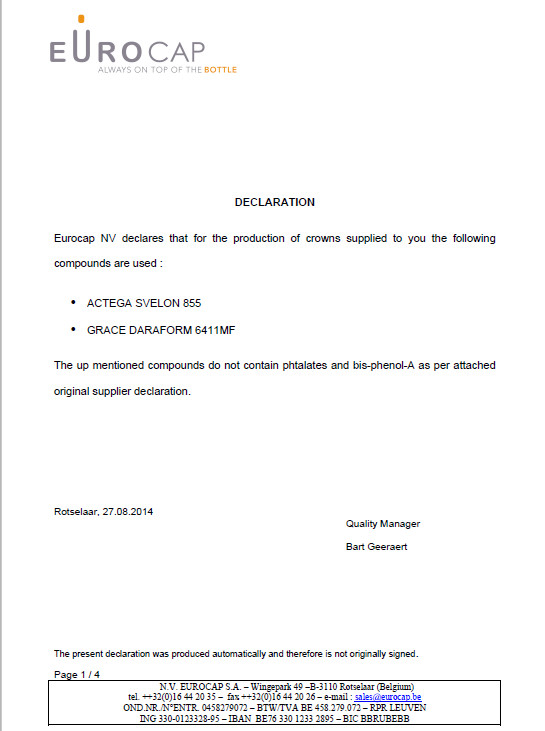

Crown Caps EUROCAP Bisphenol EN

Crown Caps EUROCAP Bisphenol EN

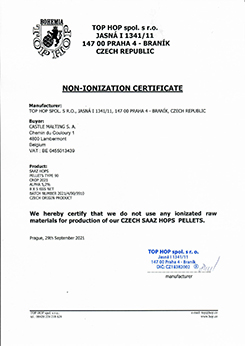

Top Hop - Non Ionization Certificate 2021

Top Hop - Non Ionization Certificate 2021