Seu carrinho

Novidades da empresa

E-Malt news

India: Pernod Ricard retains position as India�s largest alcoholic beverage maker by value

China: Tsingtao Brewery focusing on portfolio optimization and channel expansion

USA, MA: Wandering Star Craft Brewery�s time in the Berkshires comes to an end

USA, NY: Fifth Frame Brewing Co. announces abrupt and immediate closure

Nossos maltes

Nossos lúpulos

New Hops

Nossos fermentos

Nossas especiarias

Nossos candy sugars

Nossas tampinhas

-

Kegcaps 74 mm, Vermelhas 102 Flatfitting A-type (700/caixa)

Adicionar

Kegcaps 74 mm, Vermelhas 102 Flatfitting A-type (700/caixa)

Adicionar

-

Crown Caps 26 mm TFS-PVC Free, Amarelas col. 2165 (10000/caixa)

Adicionar

Crown Caps 26 mm TFS-PVC Free, Amarelas col. 2165 (10000/caixa)

Adicionar

-

CC29mm TFS-PVC Free, Azuis without oxygen scav.(7500/caixa)

Adicionar

CC29mm TFS-PVC Free, Azuis without oxygen scav.(7500/caixa)

Adicionar

-

Kegcaps 69 mm, Marrom 141 Grundey G-type (850/caixa)

Adicionar

Kegcaps 69 mm, Marrom 141 Grundey G-type (850/caixa)

Adicionar

-

CC29mm TFS-PVC Free, Amarelos with oxygen scav.(6500/caixa)

Adicionar

CC29mm TFS-PVC Free, Amarelos with oxygen scav.(6500/caixa)

Adicionar

Receitas de cerveja e uísque

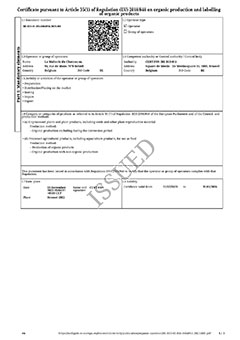

Certificados

-

Organic Certificate ENG: Malt, Hops, Spices and Sugar - Jul 2025-Mar 2028

Organic Certificate ENG: Malt, Hops, Spices and Sugar - Jul 2025-Mar 2028

-

Fagron Spices, IFSFood Certificate 16089, FR 2024

Fagron Spices, IFSFood Certificate 16089, FR 2024

-

La Malterie du Château | FCA Malt Certificate (Français) (2024-2027)

La Malterie du Château | FCA Malt Certificate (Français) (2024-2027)

-

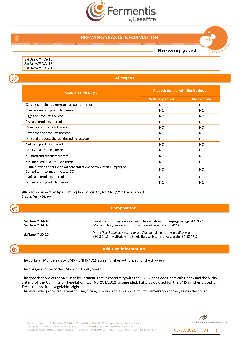

Fermentis - Brewing Yeasts Information ENG - HA-18,_DA-16, LD-20

Fermentis - Brewing Yeasts Information ENG - HA-18,_DA-16, LD-20

-

Hollands Hophuis, NON-Ionised, NON-GMO Certificate 2023

Hollands Hophuis, NON-Ionised, NON-GMO Certificate 2023

Sugestão

USA: Coors Brewery could become a producer of innovative car fuel

USA: Coors Brewery could become a producer of innovative car fuel

Coors Brewery in near future could become, besides a famous beer producer, a producer of innovative car fuel. According to a news report for CNN Money, Coors uses waste from the beer production process to produce approximately 1.5 million gallons of ethanol, which is afterwards sold in the wholesale market.

Coors in partnership with area engineering firm Merrick & Company produce the alternative fuel. Coors stated they plan to build another ethanol facility due to the success of the program: "We've basically taken a waste stream and turned it into a revenue stream," said Steven Wagner, the Merrick vice president who oversees the ethanol project.

The ethanol’s demand, which is a gasoline substitute, is at an all-time high in the U.S, as the country has faced rising energy costs, particularly gasoline. The whole process of ethanol producing involves taking the beer waste and putting it through a two-hour refining process that leaves behind 200-proof ethanol, according to the paper. After being mixed with gasoline, the resulting fuel is then shipped out to various gas stations in the region.

The second facility, which will double Coors' ethanol production would transform into ethanol the millions of gallons of by-product from Coors brands.

Voltar