Uw winkelwagen

Uw winkelwagen is leeg

Bedrijfsnieuws

Onze kruiden

Onze suikers

Onze kroonkurken

-

Kegcaps 74 mm, Gold 116 Flatfitting A-type (700/box)

Toevoegen aan kar

Kegcaps 74 mm, Gold 116 Flatfitting A-type (700/box)

Toevoegen aan kar

-

Kegcaps 69 mm, Red 102 Grundey G-type (850/box)

Toevoegen aan kar

Kegcaps 69 mm, Red 102 Grundey G-type (850/box)

Toevoegen aan kar

-

Kroonkurken 26mm TFS-PVC Free, Bordeaux Red col. 20025 (10000/box)

Toevoegen aan kar

Kroonkurken 26mm TFS-PVC Free, Bordeaux Red col. 20025 (10000/box)

Toevoegen aan kar

-

Crown Caps 26mm TFS-PVC Free, Purple col. 2277 (10000/box)

Toevoegen aan kar

Crown Caps 26mm TFS-PVC Free, Purple col. 2277 (10000/box)

Toevoegen aan kar

-

Crown Caps 26 mm TFS-PVC Free, Dark Brown col. 2844 (10000/box)

Toevoegen aan kar

Crown Caps 26 mm TFS-PVC Free, Dark Brown col. 2844 (10000/box)

Toevoegen aan kar

Bier Recepten

Woordenlijst

See sucrose.

Having an astringent taste.

A strongly astringent substance obtained from gall nuts, sumac, etc., used in chillproofing of beer. Also present in hops and malt in small amounts.

Taste sensation cause by acidic flavors.

Gray sludgy protein material that settles on top of the mash during sparging.

In all-grain brewing, refers to bringing the mash to a specified temperature, and holding that temperature for a specified period of time.

Hardness in water that can be removed by boiling.

The specific gravity of the wort after fermentation has ended. Sometimes called final gravity.

Group of flavor chemicals forming the main component of hop oils.

Sugar molecule consisting of four simple sugars (monosaccharides) linked together.

A device used to measure temperature. A thermometer is indispensable for monitoring and maintaining mash schedules. Thermometers are characterized by their displays and are available in liquid scale, analog dial and digital versions.

Thermometers commonly used in home brewing fall into three broad categories - the traditional liquid (alcohol or mercury) type; dial thermometers; and digital thermometers. Liquid thermometers are reasonably accurate, but have the disadvantage of being fragile; furthermore, mercury is highly toxic -- the use of mercury thermometers in brewing is not recommended. Dial thermometers are reasonably rugged, usually liquid-proof, and respond quickly, but may suffer from poor accuracy. Digital thermometers are available in a wide variety of styles and price ranges; the cheapest digital models generally cost around $15, are typically not liquid-proof, and are plenty accurate enough for mashing.

Heat loving. Thermophilic bacteria are bacteria that thrives at unusually high temperatures.

The process, operation, or method of determining the concentration of a substance in solution by adding to it a standard reagent of known concentration in carefully measured amounts until a reaction of definite and known proportion is completed, as shown by a color change or by electrical measurement, and then calculating the unknown concentration.

Malt which has been heated in an oven or kiln, to impart a toasted flavor. Biscuit malt and victory malt are commercially available toasted malts.

Yeast which tends to rise to the surface of the beer as fermentation progresses. Top cropping yeasts were traditionally harvested for repitching by skimming them off the surface of the fermenting wort. In some cases, top cropping strains will need to be "beaten" back into the wort periodically, to achieve complete fermentation in a reasonable period of time. See also bottom cropping.

A style of yeast that works at cellar or warm temperatures and floats to the top of the beer. Ale yeasts are responsible for the creation of most beers other than lagers. However, this style of brewing is practiced mostly in England and very few breweries in the US use this type of yeast to produce real ales. Instead, US ales are made with a modified lagering process.

Torrefaction occurs when a cereal (barley, maize, oats, wheat, etc.) is treated at high temperature to gelatinise the starch endosperm creating the expansion of the grain and creating a puffed appearance. The cereal can then be used whole or flaked. In brewing, the use of small quantities of torrefied wheat or barley in the mashing process aids in head retention and cling to the glass.

A poisonous substance produced by certain microorganisms.

A strong ale made at one of the last five brewing Trappist monasteries in Belgium and The Netherlands. They are widely regarded as the finest beers in the world.

A sugar molecule which consists of three linked simple sugars.

1. The flocculated yeast and break material which collects at the bottom of the fermenter.

2. In the process of brewing beer, trub (from the German for lees) is the layer of sediment that appears at the bottom of the fermenter after yeast has completed the bulk of the fermentation. It is composed mainly of heavy fats, proteins and inactive yeast.

Trub also refers to the material, along with hop debris, left in the boil kettle or hopback after the wort has been transferred and cooled. Brewers generally prefer that the bulk of the trub be left in the kettle rather than stay in contact with the fermenting wort. Although it contains yeast nutrients, its presence can impart off-flavors in the finished beer.

2. In the process of brewing beer, trub (from the German for lees) is the layer of sediment that appears at the bottom of the fermenter after yeast has completed the bulk of the fermentation. It is composed mainly of heavy fats, proteins and inactive yeast.

Trub also refers to the material, along with hop debris, left in the boil kettle or hopback after the wort has been transferred and cooled. Brewers generally prefer that the bulk of the trub be left in the kettle rather than stay in contact with the fermenting wort. Although it contains yeast nutrients, its presence can impart off-flavors in the finished beer.

The tulip glass looks somewhat like a tulip - go figure. It can have a stemmed base and roundish bowl, which thins out about 1/2 way up the glass then flares out slightly. It can also be similar in style to a pint glass, but has the tulip flare. Holds 16 oz.

Any large vessels used in brewing.

Sediment or foreign particles stirred up or suspended.

Cane sugar which has not been fully refined. Still contains some of the natural molasses, giving it a golden color, and a rum-like flavor. Sometimes called raw sugar.

Malt which has been made from two row barley. Two row barley has larger kernels, a lower protein content, and a lower husk content than six row barley. This gives two row malt a slightly higher extract potential than six row malt, and makes it less prone to causing chill haze. Most high quality brewers malts are two row malts.

The practice of racking the beer to a second fermentation vessel after activity begins to subside; this gets the beer off of the large sediment deposit that is typically present in the primary fermenter, and prevents the pick-up of off flavors from yeast autolysis. The beer is left in the secondary fermenter until it has completely fermented out and fallen clear. Two-stage fermentation is generally recommended for lagers and strong ales, where the beer is likely to remain in the fermentation vessel for some time prior to being bottled or kegged. For normal strength ales, two-stage fermentation it is optional, but can still help reduce the amount of bottle sediment, by minimizing the amount of sediment carried over into the bottling bucket.

Certificat Bio Paille de riz FR - 2025 - 2027

Certificat Bio Paille de riz FR - 2025 - 2027

Fermentis - Spirit Dry Yeast Information 2023

Fermentis - Spirit Dry Yeast Information 2023

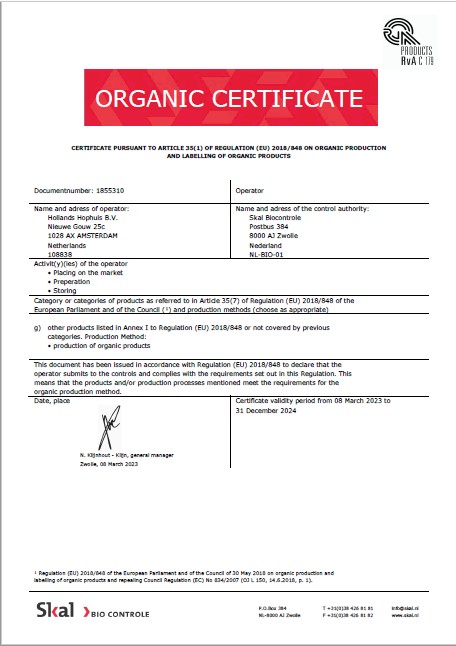

Hollands Hophuis, Organic Production and Labelling 2023-2024

Hollands Hophuis, Organic Production and Labelling 2023-2024

Fagron Spices, GMO-free Certificate 2022

Fagron Spices, GMO-free Certificate 2022