Ваш кошик

Ваш кошик порожній

Новини компанії

Наші спеції

Наш цукор

Наші кришки

-

Кришки 26mm TFS-PVC Free, Cyan Opaque col. 2616 (10000/Коробка)

Додати до кошика

Кришки 26mm TFS-PVC Free, Cyan Opaque col. 2616 (10000/Коробка)

Додати до кошика

-

Crown Caps 26mm TFS-PVC Dark Green col. 2410 Зелені (10000/Коробка)

Додати до кошика

Crown Caps 26mm TFS-PVC Dark Green col. 2410 Зелені (10000/Коробка)

Додати до кошика

-

Кришки 26mm TFS-PVC Free, Gold Neu Matt col. 2981 (10000/Коробка)

Додати до кошика

Кришки 26mm TFS-PVC Free, Gold Neu Matt col. 2981 (10000/Коробка)

Додати до кошика

-

Кришки для кег 64мм, Білий 86 Sankey S-тип (ЄС) (1000/Коробка)

Додати до кошика

Кришки для кег 64мм, Білий 86 Sankey S-тип (ЄС) (1000/Коробка)

Додати до кошика

-

Кришки 26mm TFS-PVC Free, Mustard yellow col. 20164 (10000/Коробка)

Додати до кошика

Кришки 26mm TFS-PVC Free, Mustard yellow col. 20164 (10000/Коробка)

Додати до кошика

Рецепти пива

Словник

The conversion of soluble starches to sugars via enzymatic action.

In grain mashing, a temperature rest which allows amylase enzymes in the malt to convert starches into sugars. The saccharification rest is typically in the 149-160°F temperature range. Temperatures at the low end of this range will produce a more fermentable wort, with a high percentage of simple sugars; this will result in a thinner, drier beer (lower finishing gravity). Temperatures at the high end of this range will produce a wort which contains a higher percentage of complex sugars and dextrins, which are not fermentable by brewers yeast; this will result in a heavier, sweeter beer (higher finishing gravity).

Any devise for measuring the amount of sugar in a solution. A specially calibrated hydrometer.

Lager or bottom fermenting yeast.

Genus and species name of yeasts used for brewing beer. In the past only ale yeasts were classified as Saccharomyces cerevisiae and lager yeasts were classified as Saccharomyces uvarum. Now both yeasts have been lumped together under the name Saccharomyces cerevisiae.

Formerly the genus and species name of lager yeast. Has been reclassified to Saccharomyces cerevisiae and is now classified as the same species as ale yeasts.

A bottle, 9 liters in capacity.

A class of compounds formed when the hydrogen of an acid is partly or wholly replaced by a metal or a metallic radical. Specifically, the term salt is applied to sodium chloride, NaCl.

Flavor like table salt; experienced on the side of the tongue.

The never-ending process of cleaning brewing equipment.

To reduce microbial contaminants to insignificant levels.

A dilute solution containing a small amount of a chemical sanitizing agent, mixed with water. Typically used for soaking equipment, or applied to equipment by wiping or spraying.

This device connects the gas line and the beer line to the keg. The keg sankey is also the device that opens the valve in the keg allowing the beer out, and the gas in. Most domestic brewers use the "D" system keg sankey. Acronym: Keg Tap

A solution which contains any constant temperature as much dissolved Solution substance as it can possibly hold in presence of solid solute.

Type of glass tapering from top to bottom. Generally used for lagers. (Also a sherry glass and a boat)

The weighted average of a particular beer. The more ratings the beer has, the closer it comes to it's actual average.

A top-fermented beer of Scottish origin. Traditionally strong, very dark, thick and creamy.

A Scottish-style ale that is less alcoholic than its Scotch ale cousin.

A beer brewed for a specific season of the year, such as an Octoberfest or winter warmer.

The lighter, more dilute runnings which come out of the lauter tun after the addition of sparge water. In a parti-gyle scheme, the first runnings are used to brew a very strong beer (e.g. a Barleywine), while the second runnings are used for a lower gravity beer (i.e. a small beer).

A period of settling and conditioning of the beer after primary fermentation and before bottling.

The vessel to which the beer is transferred after most of the fermentation activity has subsided.

A regulator not connected directly to the gas source and normally located in the cooler. Typically, the Secondary Regulator is installed between the Primary Regulator and a keg coupler to enable the Ideal Gauge Pressure to be set for individual beer kegs.

The yeast and fermentation byproducts at the bottom of a bottle of conditioned beer - typically rich in vitamin B.

Yeast used to start fermentation in a brew.

The only beer glass with a handle. Typically very heavy and sturdy. They can have different textures and come in different sizes. Also called a mug or krug.

The vessel from which beer is served.

A low-alcohol beer brewed so several can be consumed in one drinking session.

See stuck sparge.

A procedure used to avoid compacting the grain bed. In this procedure the lauter tun is filled to one eighth-inch above the false bottom with 175 °F (79 °C) water. Then the mash is put into the lauter tun. This procedure prevents compacting of the grain bed by providing support for the grains as they enter the lauter tun. This is used when you have separate mash and lauter tuns.

Most specific to England, when a beer is not poured to the fill line. In other words, you ordered a pint, but did not receive a full pint.

A hard, glassy substance made from specially processed silica (sand), which contains microscopic pores. Sometimes used as a beer clarification agent; can also be used as a dessicant (moisture absorber), due to its extreme attraction for water.

An ion that causes haze.

A tower shaped structure for storage of materials.

The casual fashion of aceofhearts.

More properly, single temperature infusion; the classic British method in which the mash is mixed and held at a single temperature until starch conversion is complete.

The practice of carrying out the entire fermentation in a single vessel. For beers which will be ready to bottle or keg within a couple of weeks (i.e. average gravity ales), a single-stage fermentation is all that is required. See also two-stage fermentation.

A pipe or tube fashioned or deployed in an inverted U shape and filled until atmospheric pressure is sufficient to force a liquid from a reservoir in one end of the tube over a barrier higher than the reservoir and out the other end.

This malt variety has six distinct seed rows on the grain head. Very high diastatic power allows mashing with up to 60% grain adjuncts, great if added diastatic strength is needed in a recipe. Six-Row also has greater husks per weight ratio than two-row. Protein rest recommended to avoid chill-haze.

Malt which has been made from six row barley. Six row barley has smaller kernels, and (frequently) a higher enzyme, protein, and husk content than two row barley. Six row malt may be desirable when brewing beers which contain large quantities of unmalted adjuncts -- the high enzyme content aids conversion of the adjuncts; the adjuncts dilute the protein level; and the higher husk content helps prevent a stuck sparge (adjuncts are frequently sticky).

See light-struck.

Faint "skunk" aroma caused by overexposure of beer to light.

Calcium hydroxide. Used to precipitate bicarbonate from water.

A method of storing yeast cultures. A liquid agar media is placed in vials or test tubes, and allowed to harden, while the vials are held at an angle (hence the name "slants"). The media is then innoculated with yeast, the tubes are sealed, and stored under refrigeration. When the yeast is to be used, sterile wort is added to the vial to activate the yeast; the culture is then stepped up multiple times until a pitchable volume of yeast is obtained.

A low gravity beer brewed from the second runnings of a mash, after the first runnings have been used to brew a stronger beer.

Sierra Nevada Pale Ale.

Stainless steel kegs, typically 5 gallons in capacity, originally designed for use in the soft drink industry. Often referred to as corny kegs. Soda kegs are a popular method for packaging homebrew.

Common table salt, chemical formula NaCl. Sometimes used as a water additive, when brewing certain styles of beer.

Water with the absence of bicarbonate, magnesium and calcium ions in the supply. Less than 100 ppm CaCO3.

The dissolving of a substance into solution.

A Belgian style of ale, of which the best-known example is brewed by Rodenbach.

Vinegarlike or lemonlike; can be caused by bacterial infection.

To spray grist with hot water to remove soluble sugars (maltose) from the malted barley. This takes place after the mash, in a tank fitted with a false bottom (lauter tank).

A device used to deliver an evenly dispersed spray of water over the grain bed in the mash/lauter tun. The spray is employed to make sure the grain bed is not disturbed during sparging.

A very dark caramel malt made by DeWolf Cosyns of Belgium. Will impart color, and a rich, caramel/toffee/raisin flavor if used in sufficient quantity.

Typically used to refer to any malts which are added to the grist (or steeped in the brewing water in extract brewing), to impart special colors and/or flavors. Crystal/caramel, toasted, and roasted malts are specialty grains.

A measure of wort's density in relation to the density of water, which is given a value of 1 at 39.2 degrees F (4 degrees C). The addition of sugars (during mashing and sparging) raises specific gravity, while the coversion of sugars into alcohol (during fermentation) lowers specific gravity.

Ascospore formation, reproduction by division of the cell contents.

Same as dried malt extract.

Same as dried malt extract.

Brewers' term for a square fermenting vessel.

Standard Reference Method. A method of measuring color intensity roughly equal to Lovibond degrees, used by the ASBC (American Society of Brewing Chemists). Expressed as 10 times the absorbance of beer, as measured at 346 nm. This system has largely replaced the older Lovibond color rating system in the brewing industry. The Europeans use a unit called EBC "(European Brewery Convention) degree." To convert between the two use these formulas: 1 °SRM = 0.375 °EBC + 0.46 or 1 °EBC = 2.65 °SRM - 1.2.

Develops in the presence of oxygen as the beer ages or is exposed to high temperatures; winey, wet cardboard, papery, rotten vegetable, pineapple, sherry, baby diapers. Often coupled with an increase in sour, harsh, or astringent taste. Also known as oxidized flavor.

Is a taller, thinner version of the pilsner glass. Holds 12 oz. Also called a stick.

Organic compounds consisting of very long chains of linked sugar molecules. Starch is the primary component of the grains most commonly used in brewing. Starch is converted (broken down) into sugars by amylase enzymes, during mashing. Starch is not directly fermentable by brewers yeast (though certain bacteria can digest it).

In all-grain brewing, the process which converts starches in the malt into fermentable sugars. Conversion occurs under the influence of amylase enzymes present in the malt, which chop up the large starch molecules into smaller sugar molecules.

A haze in the finished beer which results from the presence of unconverted starch. Starch haze differs from chill haze in that it is present regardless of whether the beer is chilled, or at room temperature.

A small volume of wort mixed with yeast. Used to increase the yeast population before introduction into the main wort. Liquid yeast cultures should always be used with a starter, as the population is not nearly sufficient to achieve ideal fermentation. Use of 2 packages of dry yeast gives sufficient population such that a starter is not required.

The standard deviation, describes the average variance of a beer's ratings to the beer's average. The greater the standard deviation, the more disagreement there is between raters.

A quality of raw or under-modified malt in which portions of the grains are hard and "steely." These hard ends resist milling and saccharification.

The soaking of crushed specialty grains in hot (approximately 160°F) water, in order to extract fermentable sugars, color, and flavor. Commonly done by extract brewers, to add character to the beer.

A grain mash in which multiple temperature rests are employed, and the temperature boosts from one rest to the next are accomplished by carefully measured additions of boiling water.

A grain mash in which multiple temperature rests are employed.

The filtering of beer through a filter with pores so fine that all yeast and bacteria are removed. Sterile filtration is sometimes used by commercial breweries, as an alternative to pasteurization. The drawback of sterile filtration is that it can remove some desirable characteristics (flavor and body) from the beer.

To eliminate all forms of life, especially microorganisms, either by chemical or physical means.

Any of various solid steroid alcohols widely distributed in plant and animal lipids.

The process by which crystal malts are produced. Whole damp malt is heated to saccharification temperatures, allowing the amylase enzymes which are naturally present in the malt to convert the starches into sugars. The malt is then kilned (heated), to dry it and impart color and flavor.

This is a taller, thinner version of the pilsner glass. Holds 12 oz. Also called a stange.

The target temperature of a mash rest, the temperature at which a desired reaction occurs.

The water which is used to mix with the grist at mash in.

Adding hot water to grist to start the mash process.

The strongest "grade" of English Bitter.

In all-grain brewing, the inability to get any liquid to flow through the grain bed during the sparge. Generally only an issue with mashes containing a high percentage of wheat, or unmalted adjuncts. Rice hulls can be added to the mash, to reduce the risk of a stuck sparge.

This disaccharide consists of a fructose molecule joined with a glucose molecule. It is most readily available as cane sugar. Sucrose is generally not used in brewing, as it will result in a cidery aroma.

Compounds which produce a sulfury, rotten egg, burnt rubber, or striking match aroma in a beer which can form during fermentation under certain conditions.

Basic taste associated with sugar, taste sensation on tip of the tongue.

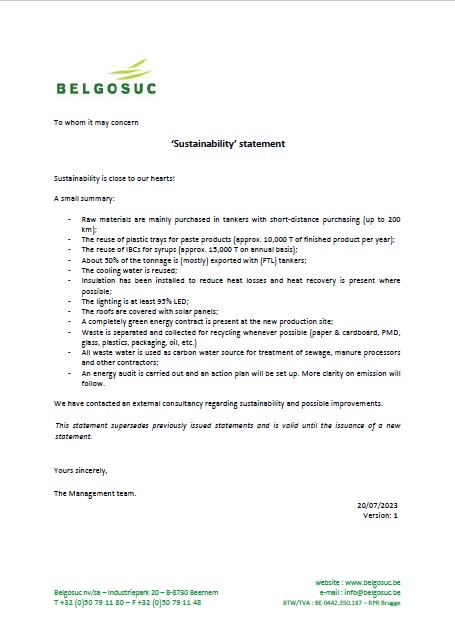

Belgosuc Sugar, Sustainability certificate 2023

Belgosuc Sugar, Sustainability certificate 2023

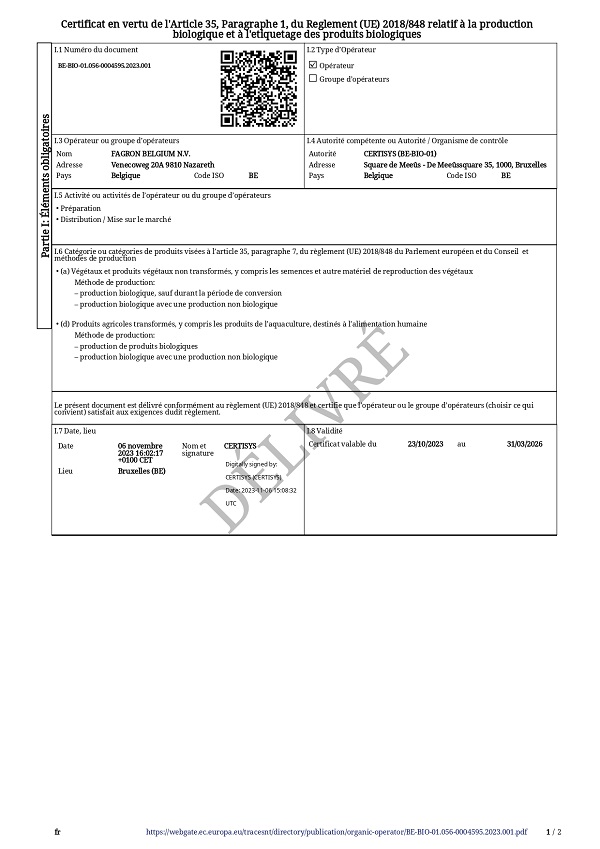

Fagron Spices, Organic Certificate 2023 - 2026

Fagron Spices, Organic Certificate 2023 - 2026

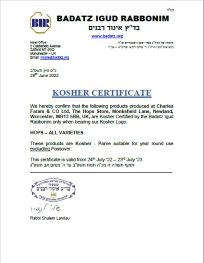

ChF - Hops Kosher Certificate 2022-2023

ChF - Hops Kosher Certificate 2022-2023

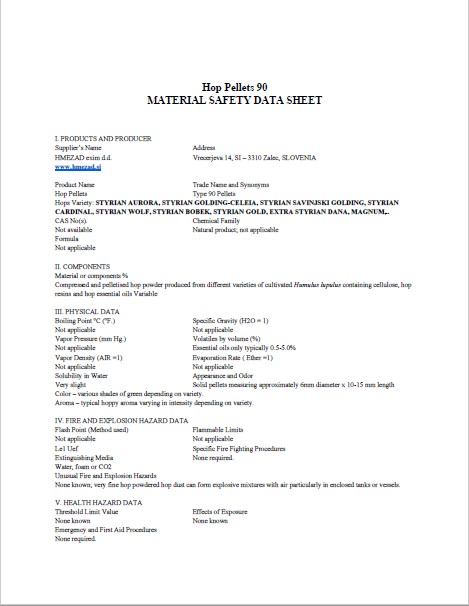

HMEZAD Hops - Material Safety data sheet 2022

HMEZAD Hops - Material Safety data sheet 2022

Belgosuc Sugar, Irradiation’ statement, 2020

Belgosuc Sugar, Irradiation’ statement, 2020