Ваш кошик

Ваш кошик порожній

Новини компанії

Наші спеції

Наш цукор

Наші кришки

-

Кришки для кег 69 мм, Чорний 91 Grundey G-тип (850/Коробка)

Додати до кошика

Кришки для кег 69 мм, Чорний 91 Grundey G-тип (850/Коробка)

Додати до кошика

-

Кришки для кег 69 мм, Коричневі 141 Grundey G-тип (850/Коробка)

Додати до кошика

Кришки для кег 69 мм, Коричневі 141 Grundey G-тип (850/Коробка)

Додати до кошика

-

Кришки для кег 69 мм, Золотисті 116 Grundey G-тип (850/Коробка)

Додати до кошика

Кришки для кег 69 мм, Золотисті 116 Grundey G-тип (850/Коробка)

Додати до кошика

-

Кришки для кег 64мм, Orange 43 Sankey S-тип (ЄС) (1000/Коробка)

Додати до кошика

Кришки для кег 64мм, Orange 43 Sankey S-тип (ЄС) (1000/Коробка)

Додати до кошика

-

Кришки 26mm TFS-PVC Free, Bordeaux Red col. 20025 (10000/Коробка)

Додати до кошика

Кришки 26mm TFS-PVC Free, Bordeaux Red col. 20025 (10000/Коробка)

Додати до кошика

Рецепти пива

Словник

Barrel aged. Also beer advocate.

Virus that lives in and kills bacteria. Also called phage.

Bacteria inhibiting.

Any of a large group of microscopic organisms with a very simple cell structure. Some manufacture their own food, some live as parasites on other organisms, and some live on decaying matter. (See Prokaryote)

Refers to the overall harmony of flavors in a beer. More specifically, it usually refers to the levels of hops and malts. For example, if a beer's taste is predominately malt oriented, it is said to be balanced toward malts.

The most common type of keg fitting used on soda kegs, for the liquid and gas connections. The quick-disconnect locks onto a groove in the keg fitting using a spring-loaded collar, and small steel ball bearings.

A bottle, 12 liters in capacity.

A cereal of the genus Hordeum, a member of the Gramineae or grass family of plants that also includes wheat, rye, oats, maize, rice, millet and sorghum. There are two varieties (2-row, 6-row) classified according to the number of rows of seeds on each of the heads of the plant.

When malted, barley is the cereal grain preferred for brewing because the seed is covered by a husk that protects the germ during malting and helps to filter the wort during lautering by forming a filter bed. The essential qualities for brewing barley are high starch content, sufficient diastatic power to transform the starch into sugar, and low protein content.

When malted, barley is the cereal grain preferred for brewing because the seed is covered by a husk that protects the germ during malting and helps to filter the wort during lautering by forming a filter bed. The essential qualities for brewing barley are high starch content, sufficient diastatic power to transform the starch into sugar, and low protein content.

Processed barley. See barley and malt.

Seed of the barley plant.

A high alcohol, quite malty, English style beer. Alcohol levels are usually between 8.5% and 12% ABV.

Liquid yeast appearing as froth on fermenting beer.

In all-grain brewing, the malt which provides the enzymes for starch conversion, and most of the fermentable sugars. Base malt is always fairly light in color, because the high kilning temperatures used to produce darker malts would kill off the enzymes.

Aromas associated with dusty, moldy, dank basements or caves.

The practice of adding all of the priming sugar for a batch of beer in bulk (using a bottling tank), prior to bottling.

The full volume of sparge water is mixed into the mash. The grain bed is allowed to settle, and then the wort is drained off.

Active oxygenated cleaner. Cleans without the use of chlorine or sulfites. For washing bottles and equipment: vessels, air-locks, tanks, hydrometers, utensils, bottles, hoses. Works equally as well on glass, plastics, stainless-steel, aluminum. Effective in removing beerstone and other dried bottle mineral deposits.

Similar to a pub glass, but thinner walls and they stop angling out about 2/3 of the way up the glass and become straight at this point.

A pump used to draw beer up from cellared casks without the use of pressured gas.

A device attached to a beer tower or beer shank through which beer is poured into a glass (point of dispense). An American style faucet is opened or closed in a quick one step pull to allow the beer to flow or a push to stop the flow of the beer. European faucets often have a flow control knob for adjusting the flow rate of the beer at the faucet. The faucet is sometimes referred to as a tap or a spigot.

Any homebrewer who has advanced beyond simple kit brewing, or any person who has taken (and passed) the BJCP Certification Exam.

Used to connect the keg coupler to the faucet. Comes in a variety of materials, colors and sizes. Materials might be stainless steel, vinyl, polyethylene or barrier. Vinyl line is often used in jockey boxes, or direct draw systems. Stainless Steel is often used in Draft Towers or in Special Event Coolers. Barrier and polyethylene is often used in glycol systems.

Brownish-gray, calcium oxalate and organic deposits left on fermentation equipment.

A hard organo-metallic scale that deposits on fermentation equipment; chiefly composed of calcium oxalate. Draft beer systems must be cleaned very regularly to prevent the buildup of beerstone which contributes off-flavors to beer.

A refined sugar which is produced from the juice of the sugar beet plant. One of the two forms of common table sugar (the other one being cane sugar). May be used as a source of fermentable sugars in some English and Belgian beer styles, and for bottle priming.

One of the "grades" of English Bitter, intermediate in strength between Ordinary Bitter and Strong Bitter.

A class of bitter compounds in hops, which contribute (slightly) to the bitterness that hops impart to beer. Beta acids are of minor importance, as most of the hop bitterness is actually imparted by alpha acids.

One of the two primary enzymes responsible for breaking starch down into sugar. Beta amylase is most active in the lower range of mashing temperatures (149F-155F) and is responsible for producing lower-order (smaller) sugars which are more fermentable, producing a beer with less body.

The enzyme which breaks down beta-glucans, which hold together branced starch molecules. This term is most commonly associated with George Fix, who championed the now famous 40/60/70 mashing schedule. The 40C rest breaks down beta-glucans, which in turn has been shown to give higher extraction yields.

A group of gummy carbohydrates in malt. Some varieties can cause problems with runoff, and during fermentation.

A colorless crystalline vitamin of the B complex, found especially in brewers yeast.

Belgian specialty malt. Lightly kilned, then lightly torrefied at up to 160°C malt. Biscuit malt produces a very pronounced "toasty" finish in the beer. Imparts a warm bread and biscuit-like aroma and flavour. Promotes a light to medium warm brown colour of the mash. This malt is used to improve the roasted flavour and aroma that characterize ales and lagers lending the subtle properties of black and chocolate malts. No enzymes. Must be mashed with malts having a surplus of diastatic power.

1) The perception of a bitter flavor, in beer from iso-alpha-acid in solution (derived from hops). It is measured in International Bitterness Units (IBU).

2) The taste component added by hops.

2) The taste component added by hops.

Beer Judge Certification Program. A non-profit organization which publishes beer style guidelines, sanctions homebrew competitions, and certifies beer judges.

A layered mixture of stout and lager or ale. The stout goes on top. Exists in many vareties, Guinness and Harp or Guinness and Bass being the best known.

Partially malted barley roasted at high temperatures. Black malt gives a dark colour and a roasted flavor to beer.

Malted barley which has been roasted until it is black (or nearly so) in color, using a special roasting device. May be used in small amounts to impart color to beer, or in larger amounts to impart a dark brown or black color, and a sharp, roasted character. Similar to roasted barley. May be mashed or steeped.

Common household bleach, a.k.a. sodium hypochlorite. A reasonably effective and very inexpensive cleaning and sanitizing agent for brewing equipment and beer bottles. Must be rinsed (or allowed to air dry for an extended period of time) to prevent off flavors from the chlorine reacting with compounds in the beer.

High-dried brown malt which has been allowed to torrefy, or "blow" (in a similar fashion to popping corn), increasing the volume a given mass will take up.

A type of airlock arrangement consisting of a tube exiting from the fermenter, submerging into a bucket of water, that allows the release of carbon dioxide and removal of excess fermentation material.

BudMillerCoors.

Refers to the thickness of a beer in your mouth. Can be described as Full, medium, or thin-bodied. For example, a stout should tend to be more full-bodied, while a pale lager should be thin-bodied.

Bohemian is the original name of the lands which eventually became the Czech Republic. Bohemian Pilsner, which has been popularised by Matilda Bay Brewing Company with their naming of a beer which is frequently mis-understood to be a style rather than a beer name by drinkers. Crisp, complex and well-rounded yet refreshing.

The obvious definition is bringing a liquid to a high enough temperature that it begins to evaporate. With regards to brewing, boiling causes isomerization (changing of the structure of molecules) of the alpha and beta bittering acids from hops which makes them water soluble. The longer hops are boiled (up to 75 minutes or so), the more isomerization occurs, and the more hop bitterness will be present in your beer.

Bottles of beer which over-carbonate to the point of exploding. Bottle bombs are no laughing matter, and can potentially cause serious injury. Fortunately, as long as good brewing practices are observed, bottle bombs are extremely rare. I have only had one exploding bottle of beer in over 4-1/2 years of brewing; and I'm pretty sure that was actually due to a defective bottle (the rest of the bottles in that batch were fine).

A device for crimping metal caps onto beer bottles. The most common homebrew bottle capper design is the hand-held, "double lever" type, which grabs the neck of the bottle in a metal jaw, and squeezes the cap onto the bottle. A better (though somewhat more expensive) type is the bench capper, in which the bottle is placed on a small platform, and the cap is pressed down onto the bottle, without the need to grab the neck of the bottle in a metal jaw - this stresses the bottle less (resulting in less frequent bottle breakage), and allows bottles with odd-shaped necks to be capped successfully.

A device which allows beer bottles to be filled with minimal splashing, thereby reducing aeration/oxidation of the finished beer. A typical bottle filler consists of a rigid plastic tube (metal versions are also available) long enough to reach the bottom of the bottle, and a valve which is opened by pressing the tip of the filler against the bottom of the bottle. Can be attached directly to the end of a siphon hose, or to the spigot of a bottling bucket.

A bottle of beer equals twelve ounces.

The practice of adding a small quantity of priming sugar directly to each bottle, at bottling time.

See bottling tank.

Typically, a plastic bucket with a spigot mounted near the bottom. Finished beer is siphoned into the bottling tank, where it is mixed with the priming sugar. Bottles are filled from the spigot, then capped. (Use of a bottle filler is recommended, to minimize splashing and aeration during bottle filling.)

See bottle filler.

An additional dose of yeast added at bottling time, to ensure quick and complete fermentation of the priming sugar. Unless the beer has been sitting for a very long time in the fermenter (months), the use of bottling yeast is typically not necessary, since there is still enough of the original yeast in suspension to carbonate the beer.

Yeast which tends to settle to the bottom of the fermenter as the end of fermentation approaches. Most lager yeasts are bottom cropping.

One of the two primary types of yeast used in brewing. Bottom-fermenting yeast works well at low temperatures and ferments more sugars leaving a crisp, clean taste and then settles to the bottom of the tank. Also called "lager yeast".

See aroma.

A mead in which some of the fermentable sugars come from malt; or, a mixture of ale and mead.

The sudden precipitation of proteins and resins in wort. The hot break occurs during the boil, and the cold break occurs during rapid chilling.

The break is the point in brewing when proteins coagulate, making a clearer beer. This happens both when the wort gets boiled, as well as when it chills quickly (see hot break and cold break). The material formed is called either break, or break material. It is generaly accepted that the more break you can get (or force), the better.

A yeast that gives beer a barnyard or horse-blanket flavor. Usually unwanted, this can be found in some Belgian beers to add flavor complexity.

To make beer.

Businesses that rent their facilities for do-it-yourself brewers to come in and brew their own beer.

A person who makes beer. From the Gallic word brai (or brace) originally meaning barley, and later barley mixed with water.

Brewing memorabilia, such as old beer containers and advertisements.

Equipment used to brew beer. The collective equipment used in beer production.

A restaurant-brewery that sells 25% or more of its beer on site. The beer is brewed primarily for sale in the restaurant and bar. The beer is often dispensed directly from the brewery's storage tanks. Where allowed by law, brewpubs often sell beer "to go" and /or distribute to off site accounts. Note: BA re-categorizes a company as a microbrewery if its off-site (distributed) beer sales exceed 75 percent.

Finished beer that is prepared to be bottled or kegged and served. The last stage in the brewing process before packaging.

A vessel used as a holding tank just prior to bottling or kegging beer. Beer goes into the bright beer tank just following filtration (if filtering is done) and beer may be carbonated in it with a porous carbonating stone.

A measurement of the mass ratio of dissolved sucrose to water in a liquid. It is measured with a saccharimeter that measures specific gravity of a liquid or more easily with a refractometer. A 25 dg. Bx solution has 25 grams of sucrose sugar per 100 grams of liquid. Or, to put it another way, there are 25 grams of sucrose sugar and 75 grams of water in the 100 grams of solution. Used interchangably with Plato and Balling.

A British-style, top-fermented beer which is lightly hopped and flavored with roasted and caramel malt.

A medium-dark roasted malt, not as dark as chocolate or black malt. Color is typically around 60 L; imparts a pronounced coffee/roasted flavor, seemingly out of proportion to its color. Contains starch, but no enzymes (should be mashed with pale malt). Historically, brown malt was dried over a wood or peat fire, giving it a smoky character; contemporary brown malt is not smoky.

See cane sugar.

A chemical species, such as a salt, that by disassociation or re-association stabilizes the pH of a solution.

See batch priming.

A hole in a barrel, keg, or cask from where liquid is drawn.

A mixture of minerals which may be added to brewing water, in an attempt to emulate the hard water of Burton-On-Trent, England. Consists primarily of calcium sulfate (gypsum), with other trace minerals.

The process of treating water in order to add calcium carbonate to it (originally to make it more similar to the water of Burton-on-Trent, UK)

Described as buttery or butterscotch. Sometimes caused by abbreviated fermentation, mutated yeast or bacteria. Also known as diacetyl flavor.

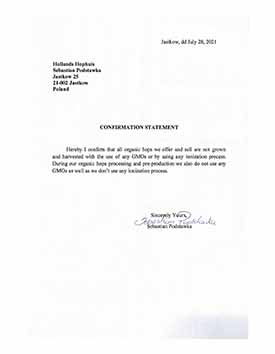

Hollands Hophuis, Confirmation Statement Organic Hops 2021

Hollands Hophuis, Confirmation Statement Organic Hops 2021

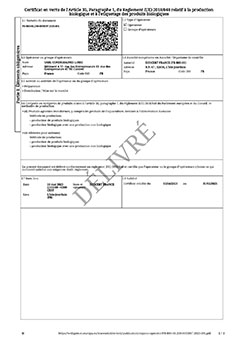

Certificat Bio Paille de riz FR - 2025 - 2027

Certificat Bio Paille de riz FR - 2025 - 2027

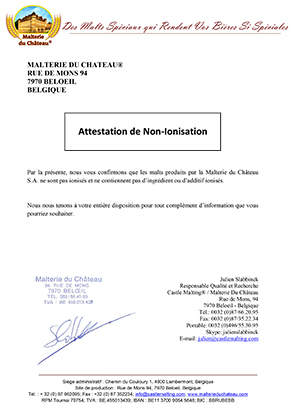

Castle Malting Malt Non Ionization Certificate FR

Castle Malting Malt Non Ionization Certificate FR

House of Hops - Non GMO / Non Ionization Certificate 2022-2023

House of Hops - Non GMO / Non Ionization Certificate 2022-2023

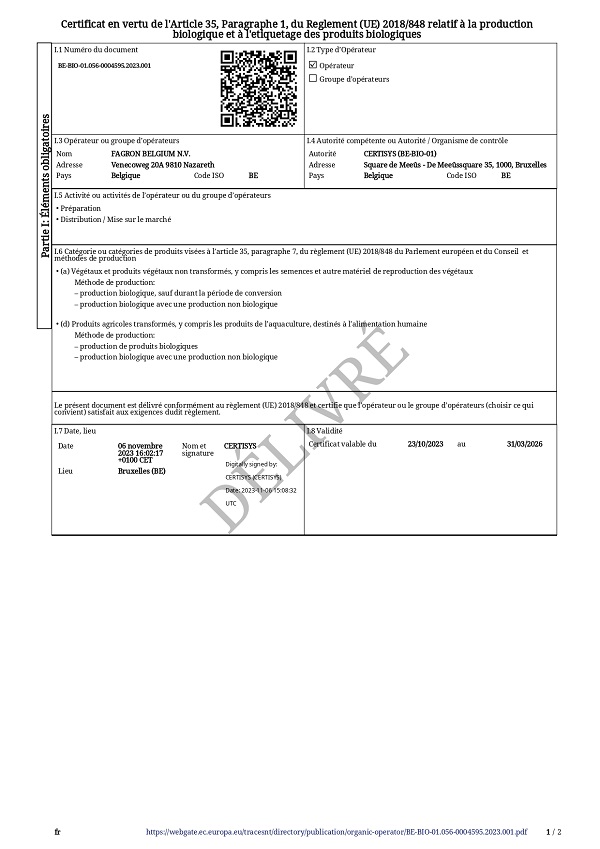

Fagron Spices, Organic Certificate 2023 - 2026

Fagron Spices, Organic Certificate 2023 - 2026