Ваш кошик

Ваш кошик порожній

Новини компанії

Наші спеції

Наш цукор

Наші кришки

-

Кришки для кег 74 мм, Чорний 91 Flatfitting A-тип (700/Коробка)

Додати до кошика

Кришки для кег 74 мм, Чорний 91 Flatfitting A-тип (700/Коробка)

Додати до кошика

-

Кришки 26mm TFS-PVC Free, Zinc opaque col. 20633 (10000/Коробка)

Додати до кошика

Кришки 26mm TFS-PVC Free, Zinc opaque col. 20633 (10000/Коробка)

Додати до кошика

-

Crown Caps 26mm TFS-PVC Free, Purple col. 2277 (10000/Коробка)

Додати до кошика

Crown Caps 26mm TFS-PVC Free, Purple col. 2277 (10000/Коробка)

Додати до кошика

-

Кришки для кег 69 мм, Orange 43 Grundey G-тип (850/Коробка)

Додати до кошика

Кришки для кег 69 мм, Orange 43 Grundey G-тип (850/Коробка)

Додати до кошика

-

Кришки для кег 69 мм, Чорний 91 Grundey G-тип (850/Коробка)

Додати до кошика

Кришки для кег 69 мм, Чорний 91 Grundey G-тип (850/Коробка)

Додати до кошика

Рецепти пива

Словник

Taste. Influenced by the grains, hops, water, yeast, and adjuncts used in production.

A base malt which has been kilned at somewhat higher temperatures than Pilsner malt. The higher kilning temperatures result in a slightly darker color, and a richer flavor.

A term used to describe the brewing process in which both malted grist and malt extract are used.

The practice of using the first runnings from the mash to brew a high-gravity (strong) beer, and the second runnings to brew a lower gravity beer. See also no-sparge brewing.

A device found at a celebration or special event where draft beer is served for a limited time. It is a self-contained device used on a keg to push the beer from the keg to the beer cup without the use of CO2. When using a party pump you should remember to keep the beer cold because as the beer warms up, foaming will increase. The beer should be consumed in 8 to 12 hours in order to avoid contamination.

Disease-causing organism.

Malt which has been dried (kilned) using a peat fire. May be used in Scottish ales, to impart a peat smoked character, similar to the smoky character that is characteristic of Scotch whiskey.

A chain of galacturonic acid that becomes gelatinous in the presence of sugars and acids.

Hops that have been dried, powdered, and pressed into pellets.

Pentose-based complex carbohydrates, found in barley as gums.

A group of simple sugars having five carbon molecules. Monosaccharides from the decomposition of pentosans, unfermentable by yeast. Includes arabinose and xylose.

A proteolytic enzyme which breaks up small proteins in the endosperm to form amino acids.

Short fragment of proteins consisting of between two and 30 amino acid molecules bound by peptide links. Peptides enhance the fullness of beer.

Soluble proteins of moderate size, intermediate between polypeptides and albumins.

Alternate name for proteolysis.

A negative logarithmic scale (1-14) that measures the degree of acidity or alkalinity of a solution for which a value of 7 represents neutrality. A value of 1 is most acidic, a value of 14 is most alkaline.

An electronic device designed to measure the pH of a solution.

Chemically treated strips of paper or plastic, which indicate the pH of a solution by changing color. A pH paper is dipped in the solution to be tested, and its color is compared against a chart supplied by the manufacturer of the papers, to determine the pH. Cheap pH papers can be difficult to "read". And if you are color-blind (like me!), most pH papers are basically useless.

Any one of a series of aromatic hydroxyl derivatives which has the OH group directly attached to the benzene ring. Specifically the term phenol is applied to carbolic acid, C6H5OH.

A roller mill designed for home brewing use, manufactured by Listermann Manufacturing. Like the other mills available to homebrewers, the Philmill appears to have a loyal following. Distinguishing features include true parallel roller adjustability, an overload spring (which prevents damage from pebbles or other foreign matter in the malt), and lower cost than its competitors. (See mill wars.)

These molecules are the source of phytic acid created during malting and during decoction or step infusion mashes. They contribute to the acidulation of the mash.

An inorganic acid, commonly used in the soft drink industry. Though harder to find than lactic acid at the homebrew level, it is slightly better as an acidifying agent for mashing/sparging, since it is more stable.

An enzyme that reduces the mash pH by creating phytic acid from the phytin of the malt. This aids saccharification, wort clarification and fermentation.

A complex organic phosphate containing both calcium and magnesium. Pale lager malt is rich in phytin.

Refers to the volume of germinating barley.

A vessel for serving cask beer, equivalent to half of a firkin.

A type of soda keg fitting where the quick-disconnect mechanism locks together by means of pins that protrude from the fittings on the keg. The pins on the keg fittings fit into grooves machined into the gas and beer hose fittings; the mechanism is locked by twisting the hose fitting.

Probably the most common beer glass. Straight, thick sides at a slight angle making the mouth of the glass larger than the base, typically holds 16 oz. You may also come across an Imperial Pint glass. These hold 20 oz. have somewhat thinner sides and a bulge about 3/4 of the way up the glass. These also come in 10 oz. half pint sizes. Also called a pub glass.

To add yeast to wort in order to induce fermentation.

The process of adding yeast to the wort in the fermentation tank.

A grain mill which crushes the grain between textured metal plates (one fixed, and one rotating). Plate mills are less desirable for brewing than roller mills, because the shearing action created by the rotating plates tends to shred the grain husks. The Corona mill is the most commonly available plate mill.

Professional brewers often use the Plato (oP) scale, instead of specific gravity, as a measure of the sugar levels in wort and beer. Very roughly, a 1.004 Specific Gravity (SG) is equivalent to 1� Plato (1% sucrose) and 1.040 to 10� Plato (10% sucrose). In other words, each Plato degree accounts for 0.004 Specific Gravity. To convert Specific Gravity to Plato, divide the digits to the right of the decimal point by 4. For example, 1.044 is 11� Plato and 1.054 is 13.5� Plato. There will not be a quiz on this.

Used in brewing industry to describe the amount of available extract as a weight or percentage of sugar in solution, in relation to specific gravity. Eg. 10 °Plato is equivalent to a specific gravity of 1.040. Used interchangably with Brix and Balling.

The fractional part of a specific gravity reading (to three decimal places). Examples: A SG reading of 1.056 is equivalent to 56 points; a SG reading of 1.105 is equivalent to 105 points.

A pokal is a European pilsner glass with a stem. Can look similar to a tulip without the flare at the top or similar to a chalice with a smaller less angular bowl. Holds 12 oz.

A beer clarifying agent, added after fermentation is complete. Polyclar is essentially a form of powdered plastic (nylon); it works by attracting haze-forming compounds, and causing them to precipitate (settle) out of solution.

A long molecule of repeated subunits.

To link together, as in the polymerization of tannins.

Long chain of amino acids joined by peptide bonds.

Polyphenols are derived from the husk and are acidic precursors of tannins. These molecules can give beer an astringent taste. Polyphenol extraction can be reduced by keeping the pH of the mash between 5.0 and 5.5. Polyphenols form complexes with proteins and are the cause of chill haze.

Complex sugars, consisting of multiple linked simple sugar (monosaccharide) molecules. Larger sugar molecules are not fermentable by brewers yeast, and will remain in the finished beer, giving it a sweet flavor.

A small, spring-loaded valve located inside a soda keg fitting. The poppet is what seals the fitting when the hose fitting is removed. Poppets are the most likely source of leaks on older soda kegs; replacements are available from various on-line vendors.

An ion that at high concentrations inhibits certain enzymes in the mash.

A hydrometer scale which can be used to directly calculate the alcohol content of the beer. Subtracting the ending (after fermentation) potential alcohol reading from the starting (before fermentation) potential alcohol reading will yield the approximate alcohol content.

Parts per billion. 1 microgram per liter.

The US homebrewers unit for total soluble extract of a malt, based on specific gravity. The unit describes the change in specific gravity (points) per pound of malt, when dissolved in a known volume of water (gallons). Can also be written as gallon*degrees per pound.

ppm - parts per million - is commonly used as unit of concentration and equivalent to milligrams per liter (mg/l)

parts per million - ppm - is commonly used as a measure of small levels of pollutants in air, water, body fluids, etc. Parts per million is the mass ratio between the pollutant component and the solution and ppm is defined as

ppm = 1,000,000 mc / ms (1)

where

mc = mass of component (kg, lbm)

ms = mass of solution (kg, lbm)

In the metric system ppm can be expressed in terms of milligram versus kg where

1 mg/kg = 1 part per million

ppm can be also be expressed as:

1 ppm = 0.0001 %

1 000 ppm = 0.1 %

10 000 ppm = 1%

parts per million - ppm - is commonly used as a measure of small levels of pollutants in air, water, body fluids, etc. Parts per million is the mass ratio between the pollutant component and the solution and ppm is defined as

ppm = 1,000,000 mc / ms (1)

where

mc = mass of component (kg, lbm)

ms = mass of solution (kg, lbm)

In the metric system ppm can be expressed in terms of milligram versus kg where

1 mg/kg = 1 part per million

ppm can be also be expressed as:

1 ppm = 0.0001 %

1 000 ppm = 0.1 %

10 000 ppm = 1%

A process, involving a material coming out of solution such as in a cold or hot break.

A substance from which another substance is derived.

See Classic American Pilsener.

The Primary CO 2 Regulator attaches to the gas source, a bottle or bulk tank and is used to decrease the tanks high gas pressure to a lower pressure. A primary regulator may be adjusted to the ideal gauge pressure and connected by gas line directly a keg coupler, or it may be installed to provide gas pressure to the Secondary CO 2 Regulator(s). Utilizes a female connector in order to connect to the gas source.

The initial fermentation activity marked by the evolution of carbon dioxide and Krausen. Most of the total attenuation occurs during this phase.

The vessel in which the initial, most active fermentation takes place.

Similar to a CO2 Primary Regulator but used for Nitrogen gas. Utilizes a male connector to connect to the source of the Nitrogen.

The method of adding a small amount of fermentable sugar and/or yeast prior to bottling to give the beer carbonation.

Sugar which is added at bottling (or kegging) time, to facilitate natural carbonation of the beer, as the sugar is fermented by the residual yeast. Pretty much any fermentable sugar can be used as priming sugar -- corn sugar (dextrose), cane sugar, malt extract, and honey are all commonly employed.

Substances that is used in beer production that are not adjuncts, malt, hops, water or yeast. Processing aids come into contact with wort or beer but are removed before the beer is consumed (unlike additives which are left in). Many filtering agents or substances used to reduce chill haze are processing aids.

To be produced or multiplied by generation. To cause to spread, to multiply as by seeds, cuttings, etc.

A proteolytic enzyme which breaks up large proteins in the endosperm that would cause haze in the beer.

1) Any one of a class of naturally occurring compounds containing carbon, hydrogen, oxygen, nitrogen, often sulfur, phosphorus, occasionally iron and a few other elements. They are essentially very complex combinations of amino acids and are constituents of all living cells, both animal and vegetable. Since most proteins contain about 16% nitrogen, it is customary in analytical chemistry to multiply the total nitrogen by the factor 6.25 in computing the percent of protein in a sample.

2) A molecule composed of amino acids. There are many types of proteins, all carrying out a number of different functions essential for cell growth.

2) A molecule composed of amino acids. There are many types of proteins, all carrying out a number of different functions essential for cell growth.

The percentage of the malt grain that is protein.

In all-grain brewing, a temperature rest in the 120-135F range, intended to break down proteins in the malt to simpler proteins and amino acids. With most modern (well-modified) malts, a protein rest is optional.

See proteolytic enzymes.

The degradation of proteins by proteolytic enzymes e.g. protease and peptidase.

Enzymes in malt, which break proteins down into simpler proteins and amino acids.

The cellular material that remains after the cell wall has been removed.

Pounds per Square Inch. A measure of gas pressure.

Probably the most common beer glass. Straight, thick sides at a slight angle making the mouth of the glass larger than the base, typically holds 16 oz. You may also come across an Imperial Pint glass. These hold 20 oz. have somewhat thinner sides and a bulge about 3/4 of the way up the glass. These also come in 10 oz. half pint sizes. Also called a pint glass.

The owner or manager of a pub.

Polyvinyl chloride, more correctly but unusually poly(vinyl chloride), commonly abbreviated PVC, is the third-most widely produced synthetic plastic polymer, after polyethylene and polypropylene.

PVC (polyvinyl chloride) is a common, low-cost plastic used in tens of thousands of products including plastic wrappers, vinyl fabrics, paint, pipes, and siding. It's all around us. Without additives or contaminants, pure PVC is actually non-toxic, but when turned into products, it's almost exclusively combined with chemicals and plasticizers. These combinations make it bad stuff for us and the planet.

When PVC is manufactured, it produces potent carcinogens and toxins including dioxins, chlorine residue, and heavy-metal pollutants. Over their lifespan, PVC products can off-gas and leak dangerous additives. PVC is also difficult to recycle; most of it ends up in landfills. When burned, it releases further dioxins and gases such as hydrogen chloride.

PVC comes in two basic forms: rigid (sometimes abbreviated as RPVC) and flexible. The rigid form of PVC is used in construction for pipe and in profile applications such as doors and windows. It is also used for bottles, other non-food packaging, and cards (such as bank or membership cards). It can be made softer and more flexible by the addition of plasticizers, the most widely used being phthalates. In this form, it is also used in plumbing, electrical cable insulation, imitation leather, signage, inflatable products, and many applications where it replaces rubber.

Pure poly(vinyl chloride) is a white, brittle solid. It is insoluble in alcohol but slightly soluble in tetrahydrofuran.

PVC (polyvinyl chloride) is a common, low-cost plastic used in tens of thousands of products including plastic wrappers, vinyl fabrics, paint, pipes, and siding. It's all around us. Without additives or contaminants, pure PVC is actually non-toxic, but when turned into products, it's almost exclusively combined with chemicals and plasticizers. These combinations make it bad stuff for us and the planet.

When PVC is manufactured, it produces potent carcinogens and toxins including dioxins, chlorine residue, and heavy-metal pollutants. Over their lifespan, PVC products can off-gas and leak dangerous additives. PVC is also difficult to recycle; most of it ends up in landfills. When burned, it releases further dioxins and gases such as hydrogen chloride.

PVC comes in two basic forms: rigid (sometimes abbreviated as RPVC) and flexible. The rigid form of PVC is used in construction for pipe and in profile applications such as doors and windows. It is also used for bottles, other non-food packaging, and cards (such as bank or membership cards). It can be made softer and more flexible by the addition of plasticizers, the most widely used being phthalates. In this form, it is also used in plumbing, electrical cable insulation, imitation leather, signage, inflatable products, and many applications where it replaces rubber.

Pure poly(vinyl chloride) is a white, brittle solid. It is insoluble in alcohol but slightly soluble in tetrahydrofuran.

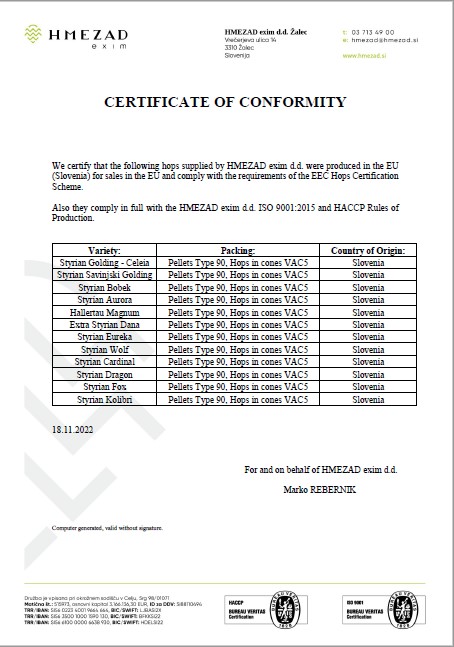

HMEZAD Hops - Certificate of conformity 2022

HMEZAD Hops - Certificate of conformity 2022

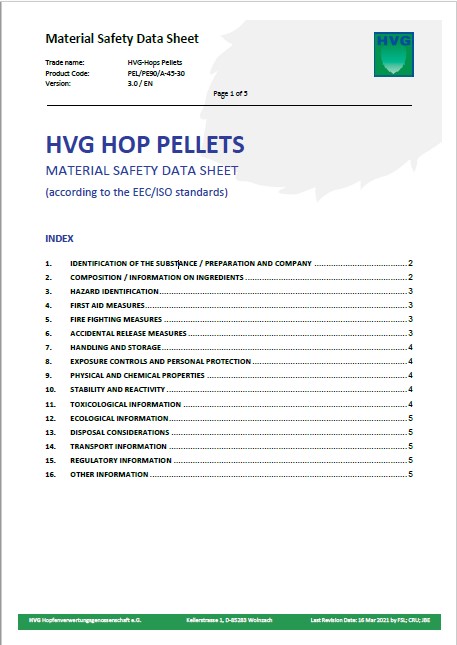

Hops, HVG, Material Safety Data Sheet 2023

Hops, HVG, Material Safety Data Sheet 2023

Fermentis - Brewing Yeasts Information ENG - Spring’Blanche

Fermentis - Brewing Yeasts Information ENG - Spring’Blanche

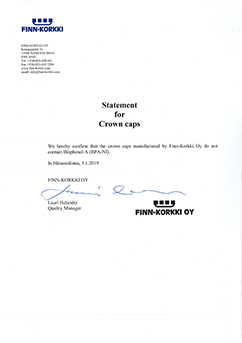

Crown Caps Finnkorkki Statement

Crown Caps Finnkorkki Statement

Malt Kosher Certificate July 2024-June 2025

Malt Kosher Certificate July 2024-June 2025