Seu carrinho

Seu carrinho está vazio

Novidades da empresa

Nossas especiarias

Nossos candy sugars

Nossas tampinhas

-

CC29mm TFS-PVC Free, Verdes with oxygen scav.(6500/caixa)

Adicionar

CC29mm TFS-PVC Free, Verdes with oxygen scav.(6500/caixa)

Adicionar

-

Crown Caps 26mm TFS-PVC Free, Orange col. 2605 (10000/caixa)

Adicionar

Crown Caps 26mm TFS-PVC Free, Orange col. 2605 (10000/caixa)

Adicionar

-

CC29mm TFS-PVC Free, Silver without oxygen scav.(6500/box)

Adicionar

CC29mm TFS-PVC Free, Silver without oxygen scav.(6500/box)

Adicionar

-

Kegcaps 74 mm, Marrom 154 Flatfitting A-type (700/caixa)

Adicionar

Kegcaps 74 mm, Marrom 154 Flatfitting A-type (700/caixa)

Adicionar

-

Kegcaps 69 mm, Douradas 116 Grundey G-type (850/caixa)

Adicionar

Kegcaps 69 mm, Douradas 116 Grundey G-type (850/caixa)

Adicionar

Receitas de cerveja e uísque

Glossário

The percentage of alpha acids in hops multiplied by the weight in ounces of the hops. Also known as Homebrew Bitterness Units (HBU). e.g. 1 ounce of Hallertauer at 5% AA has 5 AAUs.

Belgian ale, brewed in a commercial secular brewery.

Generally used to refer to any ale which has been brewed in the style of a Trappist Ale, but by a secular brewer.

Varies by region but usually the agency, Alcoholic Beverage Control.

Alcohol by volume. This is a measurement of the percent of alcohol present in a volume of liquid. To obtain this number take the original gravity and subtract the final gravity then multiply the answer by 131.25. One pound of fermentable sugar is approximately equal to 1% ABV in a 5 gallon batch. ABV = ABW x 1.25.

Alcohol by weight. This is a measurement of the percent of alcohol present in a volume of liquid. The percent is the number of grams of alcohol in 100 centiliters (e.g. 5%ABW equals 5 grams of alcohol/100 cl) - ABW = ABV x .80

Simple dextrins, from the reduction of starch by alpha amylase. Negative reaction with iodine.

A malt high in the phytase enzyme, which breaks down phytin into phytic acid, thus lowering the mash pH. Typically only used in Germany, where the Reinheitsgebot prevents brewers from using food-grade acids to do the same thing.

A relatively low temperature rest (95F) used to activate the phytase enzyme, the desired result of which is to lower the pH of the mash. This is generally only employed in Germany where the Reinheitsgebot prevents the use of things like acid blend which serve the same purpose. A small amount of acid malt is used.

The process of lowering the pH of a solution until it falls below 7.0 pH.

Process of acidifying the mash with enzymes. Temperature range: 86 to 128 dg F (30-53dg C) See acid rest.

The acrospire is the shoot of a barley plant that develops during the germination stage of the malting process.

A substance commonly used to remove both organic and inorgainic contaminants from water. Most water filtration units use activated charcoal. Does not remove all microorganisms (i.e., activated charcoal cannot be used to make unsanitary water safe).

To collect a substance on a surface; for example, protein molecules are adsorbed onto the surface of particles of silica gel.

Physical process involving adherence of particles to one another, at the microscopic level. Important in fining and other processes.

To dissolve air in a liquid. Beer wort must be well aerated before pitching to allow for healthy growth and reproduction of the yeast. This can be done in any one of several ways.

A gelatinous solidifying agent used as a culturing medium for microbial analysis or isolation.

American Homebrewers Association. Non-profit organization which promotes the hobby of homebrewing, and sanctions homebrew competitions. Founded by Charlie Papazian, author of several books on homebrewing.

A small device, designed to be affixed to the top of a fermenter. An airlock allows the CO2 produced during fermentation to escape, without allowing airborne bacteria to enter the fermenter. The most common type is called a three piece airlock, and consists of a small plastic chamber, a float which sits inside the chamber, and a dust cover. The chamber is partially filled with liquid - plain water, sanitizing solution, or vodka, depending on how paranoid you are - and the CO2 bubbles out from underneath the float. There is also a single-piece, "sideways S" type of airlock which is in fairly widespread use.

A group of soluble proteins that remain in beer, affecting head retention and stability.

The measure of the amount of space the alcohol in a beer takes up as a percentage of total volume. This is the worldwide standard for measuring the alcohol content in beer. The United States traditionally used alcohol by weight (ABW) to measure alcohol content, but more and more American brewers are now adopting ABV.

The measure of the weight of alcohol as a percentage of total weight of the liquid. This standard is being used much less frequently nowadays. To convert ABW to ABV, multiply the ABW x 1.25. Conversely, to get the ABW from ABV multiply the ABV x 0.8.

Alcohol content is measured in percent. The percentage may be either by volume or weight. Since alcohol is lighter than water, the %volume number is larger than the %weight number by a factor of 1.25. Beer in the US is commonly measured in %weight (e.g., 3.2% beer has at most 3.2% by weight of alcohol, or 4% by volume).

The general effect of ethanol and higher alcohols, warming.

A warming flavor or aroma derived from ethanol and higher alcohols. Some people think it has a salty taste.

A chemical precursor to alcohol. In some cases, alcohol can be oxidized to aldehydes, creating off-flavors.

Nutty, toffee, honey, or green apple flavors and aromas in beer caused by degradation of amino acids or oxidation of isohumulones and lipids.

Brewers yeast which typically works at temperatures of 60F and above, scientific classification Saccharomyces cerevisiae. Some (but not all) ale yeasts are top cropping - that is, they tend to float, and collect on the surface of the beer as fermentation progresses.

The living sheath surrounding the endosperm of a barley corn, containing enzymes.

The condition of pH between 7 and 14. The chief cause of alkalinity in brewing water is the bicarbonate ion (HCO3-1).

A method of brewing where pre-made malt extract powders or syrups are not used. All of the fermentable sugars are obtained by mashing malt, and (possibly) other grain adjuncts. All-grain brewing requires more equipment, and is more time-consuming than extract brewing, but gives you a great deal more control over the final product. As a rough analogy, think of the difference between baking a cake from a boxed cake mix, versus baking a cake from scratch.

A term used to describe the brewing process in which only malt grist is used with no malt extract added.

A resin contained in the hop plant that is responsible for the bitterness in beer. When purchasing hops, the alpha acid content of the hops will be given as a percentage and printed on the package cover.

A method used for specifying the quantity of bittering hops, commonly used in homebrew recipes; commonly abbreviated as AAU, and also referred to by some authors as Homebrew Bitterness Units, or HBUs. One AAU is equivalent to one ounce of hops with an alpha acid rating of 1%. Example: If a recipe calls for 10 AAUs of bittering hops, and your hops have a rating of 5%, you need two ounces. (AAUs are the same as HBUs.)

One of the two primary enzymes responsible for breaking starch down into sugar. Alpha amylase is most active in the upper range of mashing temperatures (155F-160F) and is responsible for producing higher-order (larger) sugars which are less fermentable, producing a beer with more body.

Wegen ihres hohen Bitterwertes wichtigster Inhaltsstoff des Hopfens.

Any top or bottom fermented beer having an amber color, that is, between pale and dark.

A lightly roasted (or heavily toasted?) British specialty malt. Imparts a mild roasted flavor, with hints of coffee. Color typically runs about 45 Lov. Contains starch, but no enzymes (should be mashed with pale malt).

The "medium" color grade of malt extract sold by most malt extract manufacturers. Not to be confused with amber malt, which is a different thing entirely.

The surrounding temperature.

A very light-bodied and light tasting, pale colored beer. The most common (and most popular) style of beer in North America... at least, among non-homebrewers!

An essential building block of protein, being comprised of an organic acid containing an amine group (NH2).

A group of enzymes (alpha amylase, beta amylase) present in most malted grains which are responsible for converting starches in the grain into both fermentable and unfermentable sugars. Each enzyme has a specific temperature range in which it is most active. The allgrain brewer steps her mash through a series of temperature rests in order to activate these and other enzymes.

Enzymes which convert starches to sugars. See also: alpha amylase, beta amylase.

The most complex dextrin from hydrolysis of starch with diastase. Positive reaction with iodine.

The enzymatic reduction of starch to soluble fractions.

A branched starch chain found in the endosperm of barley. It can be considered to be composed of amylose.

A straight-chain starch molecule found in the endosperm of barley.

An electro-negative ion.

The push required to propel the beer from a keg through a beer dispensing system. The Applied Pressure may be the same as the Ideal Gauge Pressure as in a kegerator beer system or it may be a much higher pressure needed to push the beer through a long draw glycol system. An Applied Pressure higher than the Ideal Gauge Pressure may over pressurize and require properly blended gas in order to avoid changing the flavor and quality of the beer in the keg.

Pertaining to, similar to, containing or dissolved in water.

The particular combination of smells from malt, hops, yeast, and any unusual or distinctive disturbances in the beer.

Varieties of hop chosen to impart bouquet. ( See Hops) Astringent -- A drying, puckering taste; tannic; can be derived from boiling the grains, long mashes, over sparging or sparging with hard water.

A medium colored specialty malt which has been kilned at temperatures higher than for a pale (base) malt, but lower than for a roasted malt. Sort of like an extra-dark Munich malt. Color is typically around 20L. Contains starch, but probably not enough enzymes to convert itself (should be mashed with pale malt).

American Society of Brewing Chemists. Standards-setting organization for beer analysis in North America.

Vitamin C, sometimes added sparingly to beer in later stages as an antioxidant.

To regulate or moderate fermentation temperature, as by maintaining ambient temperature cooler than the fermentation temperature.

A device which sterilizes through the use of extreme heat.

When yeast run out of nutrients and die, they release their innards into the beer, producing off-flavors.

Bio-Zertifikat DE - Juli 2025-März 2028

Bio-Zertifikat DE - Juli 2025-März 2028

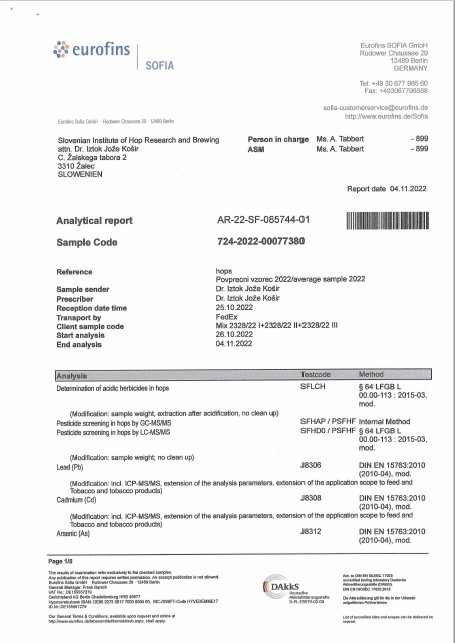

Slovenian hops Pesticide Residues Certificate (Crop 2022)

Slovenian hops Pesticide Residues Certificate (Crop 2022)

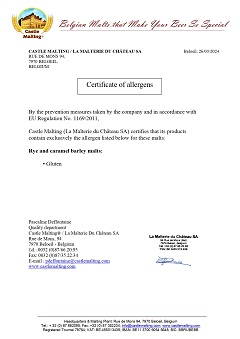

Malt Allergen Certificate for Rye and Caramel Barley Malt (ENG)

Malt Allergen Certificate for Rye and Caramel Barley Malt (ENG)

SAS Biohop Organic certificate 2023-2025

SAS Biohop Organic certificate 2023-2025

Malt Attestation of Conformity for Mycotoxins and Heavy Metals 2024 (ENG)

Malt Attestation of Conformity for Mycotoxins and Heavy Metals 2024 (ENG)