Twój koszyk

Twój koszyk jest pusty

Aktualności firmowe

Katalogi

Nasze słody

New Hops

Nasze drożdże

Beer recipe - Brown Smoked

| ABV 6.0% | Color 60 EBC | Bitterness 28 IBU |

Description

This beer is brown colored with malty, caramel hints, baked bread, and woody smoke notes.

This beer is brown colored with malty, caramel hints, baked bread, and woody smoke notes.

Service:

Glass: Goblet glass

Temperature: 4-8°C

Glass: Goblet glass

Temperature: 4-8°C

BREWER`S TIPS

Referment this beer in the bottle using SafAle BE-256 to carbonate and make it more complex.

Referment this beer in the bottle using SafAle BE-256 to carbonate and make it more complex.

RECIPE FOR 100L

MALT

| Château Pilsen 2RS | 48% / 9.7 kg |

| Château Pale Ale® | 15% / 3 kg |

| Château Munich | 10% / 2 kg |

| Château Cara Gold® | 20% / 4.1 kg |

| Château Chocolat | 2% / 0.4 kg |

| Château Peated | 5% / 1 kg |

HOPS

| Magnum (12.0% aa) | 25.5 IBU / 80 g |

| Tettnang (5.0% aa) | 2.5 IBU / 80 g |

YEAST

| SafAle BE-256 | 70 g |

Mashing temperature

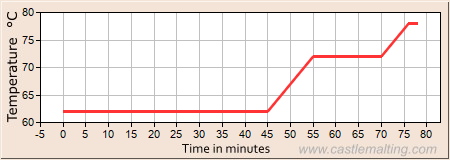

Step 1: Mashing

Mash-in and follow the profile below:

Mash-in and follow the profile below:

| pH | 5.3 | Mix Ratio | 3.0 L/kg |

Mash-in at 62°C

Rest for 45min at 62°C

Rise to 72°C at 1°C/min

Rest for 15min at 72°C and do the Iodine Test

Rise to 78°C at 1°C/min

Rest for 2min at 78°C to mash out

Once the mash is done, filter and sparge with water at 78°C

Rest for 45min at 62°C

Rise to 72°C at 1°C/min

Rest for 15min at 72°C and do the Iodine Test

Rise to 78°C at 1°C/min

Rest for 2min at 78°C to mash out

Once the mash is done, filter and sparge with water at 78°C

Step 2: Boiling

Boil for 60min.

Hop addition 1: After 10min add Magnum.

Hop Addition 2: After 50min add Tettnang.

Whirlpool to remove the trub

Boil for 60min.

Hop addition 1: After 10min add Magnum.

Hop Addition 2: After 50min add Tettnang.

Whirlpool to remove the trub

| Total evap | 6.0% | Batch size | 100L | OG | 13.0oP | Efficiency | 85% |

Step 3: Fermentation and Maturation

Cool down the wort to 16°C and pitch the yeast.

Ferment at 16°C for 2 days then rise to 20°C. Once the fermentation is done (FG reached and off-flavors removed – about 7 days), drop the temperature to 8°C and rest for 1 day, and then harvest the yeast. Drop the temperature to 2°C and rest for 10 days.

Cool down the wort to 16°C and pitch the yeast.

Ferment at 16°C for 2 days then rise to 20°C. Once the fermentation is done (FG reached and off-flavors removed – about 7 days), drop the temperature to 8°C and rest for 1 day, and then harvest the yeast. Drop the temperature to 2°C and rest for 10 days.

| Attenuation | 85% | FG | 2.00oP |

Step 4: Cold Aging and Packaging

Cold age the beer at -1°C for 5 days, remove the residual yeast, and carbonate until 2.6 volumes of CO2. The beer is ready to package and drink. Enjoy!

*For refermentation in the bottle, add brewing sugar and SafAle F-2.

Cold age the beer at -1°C for 5 days, remove the residual yeast, and carbonate until 2.6 volumes of CO2. The beer is ready to package and drink. Enjoy!

*For refermentation in the bottle, add brewing sugar and SafAle F-2.

Tę recepturę dostarcza Castle Malting®. Pomyślny rezultat nie może być zagwarantowany. Pewne zmiany mogą być konieczne, aby uwzględnić cechy charakterystyczne składników, oraz warunki technologiczne panujące w browarze.

Po więcej informacji prosimy o kontakt na adres: info@castlemalting.com

Po więcej informacji prosimy o kontakt na adres: info@castlemalting.com