Your cart

Your cart is empty

行业活动

宣传手册

我们的麦芽

New Hops

Our Yeasts

Our Spices

Beer recipe - Egyptian Beer

| ABV 7.5% | Color 48 EBC | Bitterness* 12 IBU |

Description

With a dark colour, a sweet taste and a bouquet of incredible aromas, this recipe makes use of the addition of spices, just like in antiquity, to bring greater complexity and flavour to the drink. The use of malt made from one of the first domesticated cereals, Emmer, a relative of wheat, brings a special touch to the flavour of this refreshing beer.

With a dark colour, a sweet taste and a bouquet of incredible aromas, this recipe makes use of the addition of spices, just like in antiquity, to bring greater complexity and flavour to the drink. The use of malt made from one of the first domesticated cereals, Emmer, a relative of wheat, brings a special touch to the flavour of this refreshing beer.

*The bitterness depends on the alpha acid content of hops, boiling conditions, and other parameters.

RECIPE FOR 100L

MALT

| Château Pilsen 2RS | 51.5% / 15.4 kg |

| Château Emmer Malt | 20% / 6 kg |

| Château Melano | 12% / 3.6 kg |

| Château Cara Gold® | 8% / 2.4 kg |

| Château Oat Malt | 8% / 2.4 kg |

| Château Black | 0.5% / 0.1 kg |

HOPS

| Magnum (12.0% AA) | 50 g |

YEAST

| SafAle T-58 | 80 g |

SPICES

| Ginger | 0.9 kg |

OTHER INGREDIENTS

| Dates | 3.5 kg |

| Honey | 1.5 kg |

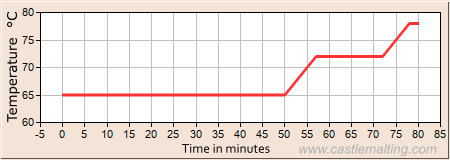

Mashing temperature

Step 1: Mashing

Mash-in and follow the profile below:

Mash-in and follow the profile below:

| pH | 5.3 | Mix Ratio | 2.7 L/kg |

Mash-in at 65°C.

Rest for 50min at 65°C. Rise to 72°C at 1°C/min.

Rest for 15min at 72°C and do the Iodine Test.

Rise to 78°C at 1°C/min. Rest for 2min at 78°C to mash out .

Once the mash is done, filter and sparge with water at 78°C.

Rest for 50min at 65°C. Rise to 72°C at 1°C/min.

Rest for 15min at 72°C and do the Iodine Test.

Rise to 78°C at 1°C/min. Rest for 2min at 78°C to mash out .

Once the mash is done, filter and sparge with water at 78°C.

Step 2: Boiling

Boil for 90 min.

Hop addition: After 30min add Magnum.

Spices addition: After 80min add dates, honey and ginger.

Whirlpool to remove the trub.

Boil for 90 min.

Hop addition: After 30min add Magnum.

Spices addition: After 80min add dates, honey and ginger.

Whirlpool to remove the trub.

| Total evap | 9.0% | Batch size | 100L | OG | 17.2oP | Efficiency | 80% |

Step 3: Fermentation and Maturation

Cool down the wort to 18°C and pitch the yeast.

Ferment at 18°C for 3 days then rise to 22°C. Once the fermentation is done (FG reached and off-flavors removed - about 7 days), drop the temperature to 8°C and rest for 1 day and then harvest the yeast.

Drop the temperature to 2°C and rest for 10 days. Please note that the OG can be affected depending on the extract yield brought by honey and dates.

Cool down the wort to 18°C and pitch the yeast.

Ferment at 18°C for 3 days then rise to 22°C. Once the fermentation is done (FG reached and off-flavors removed - about 7 days), drop the temperature to 8°C and rest for 1 day and then harvest the yeast.

Drop the temperature to 2°C and rest for 10 days. Please note that the OG can be affected depending on the extract yield brought by honey and dates.

| Attenuation | 76% | FG | 4.16oP |

Step 4: Cold Aging and Packaging

Cold age the beer at -1°C for 5 days, remove the residual yeast, and carbonate until 4.7 g/L of CO2. The beer is ready for packaging and drinking. Enjoy!

For refermentation in the bottle, add brewing sugar and SafAle F-2.

Cold age the beer at -1°C for 5 days, remove the residual yeast, and carbonate until 4.7 g/L of CO2. The beer is ready for packaging and drinking. Enjoy!

For refermentation in the bottle, add brewing sugar and SafAle F-2.

这是由Castle Malting® 提供的配方。 成功的酿制并非百分百保证。 配方及处理方法或需要稍微的改动, 视乎个别材料的特性和个别酿酒厂的技术、 环境而定。

如需要更加多的资讯和服务, 请联系: info@castlemalting.com

如需要更加多的资讯和服务, 请联系: info@castlemalting.com