Company News

Our Spices

Our Sugars

Our Caps

-

Crown Caps 26mm TFS-PVC Free, Zinc opaque col. 20633 (10000/box)

Add to cart

Crown Caps 26mm TFS-PVC Free, Zinc opaque col. 20633 (10000/box)

Add to cart

-

Kegcaps 74 mm, Black 91 Flatfitting A-type (700/box)

Add to cart

Kegcaps 74 mm, Black 91 Flatfitting A-type (700/box)

Add to cart

-

Kegcaps 64 mm, Brown 118 Sankey S-type (EU) (1000/box)

Add to cart

Kegcaps 64 mm, Brown 118 Sankey S-type (EU) (1000/box)

Add to cart

-

Kegcaps 64 mm, Red 1485 Sankey S-type (EU) (1000/box)

Add to cart

Kegcaps 64 mm, Red 1485 Sankey S-type (EU) (1000/box)

Add to cart

-

Kegcaps 74 mm, Orange 43 Flatfitting A-type (700/box)

Add to cart

Kegcaps 74 mm, Orange 43 Flatfitting A-type (700/box)

Add to cart

Beer Recipes

Glossary

To siphon the beer from one vessel to another in order to separate the beer from the lees or trub.

Siphoning, draining or pumping beer from one tank into another, leaving behind the trub, or the filling of kegs or other serving vessels.

A device which makes it easier to rack, without picking up trub and/or yeast from the bottom of the vessel being transferred from. Consists of a length of rigid plastic or metal tubing, with a stand-off device at the end, which keeps the intake above the sediment layer.

The lower portion of the axis of an embryo seedling.

A simple sugar, important in a test to differentiate ale and lager yeast, as only lager yeast can ferment it completely.

Having a smell or taste of stale fats or oils.

Malt which has been smoked, usually over a beechwood fire.

See turbinado sugar.

The term used by CAMRA for traditional cask-conditioned ale.

The actual percentage of the sugars originally present in the wort, which have been fermented by the yeast. Real attenuation is lower than apparent attenuation (which is what your hydrometer measures), because alcohol is lighter than water.

The extract in dealcoholized beer.

A bottle, 4.5 liters in capacity.

Commonly abbreviated as RIMS. A mashing system in which a pump is used to continuously recirculate the liquid part of the mash through the mash bed. Mash temperature is maintained by passing the liquid over a heating element; the heating element is cycled off and on to maintain the desired mash temperature.

The action of pumping the wort from the bottom of the mash tun and letting it fall into the surface of the mash. Also called the "Vorlauf."

Regional Brewery: A brewery with an annual beer production of between 15,000 and 2,000,000 barrels.

Regional Craft Brewery: An independent regional brewery who has either an all malt flagship or has at least 50% of it's volume in either all malt beers or in beers which use adjuncts to enhance rather than lighten flavor.

A device which is used to reduce the pressure of CO2 coming from a tank (typically around 800 PSI), to the pressure required to carbonate or dispense beer (typically 5 to 30 PSI).

A pressure-activated valve, which protects against dangerous overpressurization in a system or device. If the safe working pressure is exceeded, the relief valve "vents", releasing the excess pressure. The most common types of relief valves seen by homebrewers are on CO2 regulators, and soda kegs.

Any of numerous clear to translucent yellow or brown, solid or semisolid, viscous substances of plant origin, such as lupulin in the hop flower.

The process in which living things oxidize sugar in order to obtain energy.

The period of time during which the mash is held at a pre-determined temperature in order to activate specific enzymes.

The resistance beer encounters as it flows from a keg, through the tap, beer line and other hardware designed into a beer dispensing system. A beer system is considered to be in balance when Applied Pressure equals the Restriction and results in a Flow Rate of approximately one gallon of beer per minute. Restriction in a beer system comes from the type of beer line used and the size and length of that line, the gravity (lift or drop) in the system, the altitude at which the beer is dispensed, and the components used in the beer system. Sometimes referred to as resistance or hold back.

A means of water purification, in which a special membrane is used. The microscopic pores in the membrane allow water molecules to pass through, but remove impurities. Reverse osmosis water from a properly functioning reverse osmosis unit is nearly as pure as distilled water.

The fibrous outer casing of the rice kernel, normally removed in processing. Rice hulls are frequently added to mashes containing a high percentage of wheat or unmalted adjuncts, to help form the filter bed during sparging; this can help prevent a stuck sparge.

A sugar syrup produced from rice. May be used by extract brewers, to achieve an effect similar to that of using rice as an adjuct in a grain mash.

Recirculating Infusion Mash System - brewing setup that is quite popular among homebrewers.

Ribonucleic acid.

Unmalted barley which has been roasted. Roasted barley is the ingredient which gives many Stouts their dark color, and sharp, roasted flavor.

A device for roasting.

Term used to describe a "rocky" like texture of kraeusen, especially during primary fermentation.

A grain mill in which the kernels are crushed, by passing them between rotating rollers. A roller mill is the preferred method for crushing malt for brewing, because it breaks the kernels open, without shredding the husks. (Intact husks are required for a trouble-free sparge.)

The small immature root structures that appear during germination. These structures are removed during the malting processing.

Spoilage condition causing beer to be slimy, viscous, gelatinous blobs, or "rope. Certain bacteria produce gums, which cause this condition.

To make a yeast starter using sterile wort and N to G of the normal pitching slurry.

Creating turbulence by agitation, stirring or mixing.

Period of storage after main fermentation.

The nearly fermented beer, ready for lagering. Cold secondary fermentation.

The liquid that is separated from the spent grains during lautering or sparging. Also called runnings, wort, sweet wort or sweet liquor.

A very strong, dark (nearly black), intensely roasty and malty ale. So named because it supposedly was originally brewed (in England) for export to Russia.

A parasitic fungus on plants. Also the oxidation of iron.

Organic Rice Husk Certificate FR - 2023 - 2025

Organic Rice Husk Certificate FR - 2023 - 2025

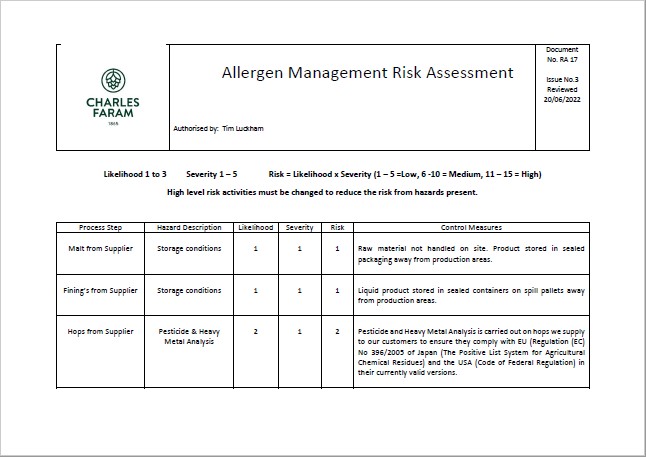

ChF Hops, RA17 Allergen Management Risk Assessment, EN 2022

ChF Hops, RA17 Allergen Management Risk Assessment, EN 2022

Hops Comptoir Agricole: Non-Ionized Certificate 2022

Hops Comptoir Agricole: Non-Ionized Certificate 2022

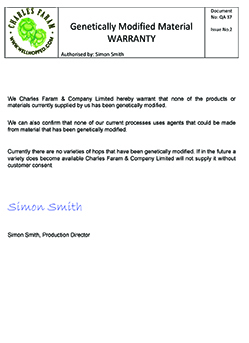

ChF Hops GMO-free Certificate

ChF Hops GMO-free Certificate

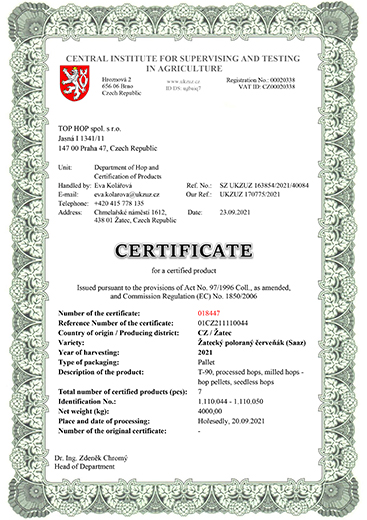

Top Hop - Variety Certificate 2021

Top Hop - Variety Certificate 2021