Tu carrito

Tu carrito está vacío

Noticias de Empresa

Nuestras maltas

New Hops

Nuestras levaduras

Nuestras especias

Beer recipe - Blond Summer Beer

| ABV 6.0% | Color 8 EBC | Bitterness 25 IBU |

Description

Thirst-quenching sweet beer. Little bitter with orange, passion fruit, and banana aromas.

Thirst-quenching sweet beer. Little bitter with orange, passion fruit, and banana aromas.

Service:

Glass: Tulip Glass

Temperature: 4-8°C

Glass: Tulip Glass

Temperature: 4-8°C

BREWER`S TIPS

Referment this beer in the bottle using SafAle F-2 to carbonate and make it more complex.

Referment this beer in the bottle using SafAle F-2 to carbonate and make it more complex.

RECIPE FOR 100L

MALT

| Château Pilsen 2RS | 89% / 17.4 kg |

| Château Wheat Blanc® | 6% / 1.1 kg |

| Château Cara Clair® | 6% / 1.1 kg |

HOPS

| First Gold (8.0% aa) | 17.5 IBU / 80 g |

| Cascade (6.0% aa) | 2.5 IBU / 80 g |

| Motueka (7.5% aa) | 2.5 IBU / 60 g |

| Sorachi Ace (13.0% aa) | 2.5 IBU / 40 g |

YEAST

| SafAle BE-134 | 60 g |

SPICES

| Bitter orange peels | 40 g |

| Cumin | 10 g |

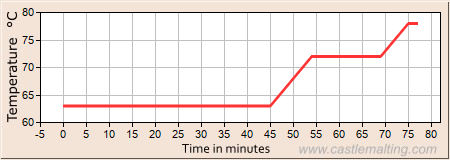

Mashing temperature

Step 1: Mashing

Mash-in and follow the profile below:

Mash-in and follow the profile below:

| pH | 5.3 | Mix Ratio | 2.7 L/kg |

Mash-in at 63°C

Rest for 45min at 63°C

Rise to 72°C at 1°C/min

Rest for 15min at 72°C and do the Iodine Test

Rise to 78°C at 1°C/min

Rest for 2min at 78°C to mash out

Once the mash is done, filter and sparge with water at 78°C

Rest for 45min at 63°C

Rise to 72°C at 1°C/min

Rest for 15min at 72°C and do the Iodine Test

Rise to 78°C at 1°C/min

Rest for 2min at 78°C to mash out

Once the mash is done, filter and sparge with water at 78°C

Step 2: Boiling

Boil for 60min.

Hop addition 1: After 10min add First Gold.

Hop addition 2: After 55min add Cascade, Motueka, and Sorachi Ace.

Spices addition: At the end of the boil add Bitter Orange Peels and Cumin.

Whirlpool to remove the trub

Boil for 60min.

Hop addition 1: After 10min add First Gold.

Hop addition 2: After 55min add Cascade, Motueka, and Sorachi Ace.

Spices addition: At the end of the boil add Bitter Orange Peels and Cumin.

Whirlpool to remove the trub

| Total evap 6.0% | Batch size 100L | OG 13oP | Efficiency 85% |

Step 3: Fermentation and Maturation

Cool down the wort to 22°C and pitch the yeast.

Ferment at 22°C for 2 days then rise to 24°C. Once the fermentation is done (FG reached and off-flavors removed – about 7 days), drop the temperature to 8°C and rest for 1 day, and then harvest the yeast. Drop the temperature to 2°C and rest for 7 days.

| Attenuation | 86% | FG | 1.80oP |

Step 4: Cold Aging and Packaging

Cold age the beer at -1°C for 5 days, remove the residual yeast, and carbonate until 2.6 volumes of CO2. The beer is ready to package and drink. Enjoy!

*For refermentation in the bottle, add brewing sugar and SafAle F-2.

Cold age the beer at -1°C for 5 days, remove the residual yeast, and carbonate until 2.6 volumes of CO2. The beer is ready to package and drink. Enjoy!

*For refermentation in the bottle, add brewing sugar and SafAle F-2.

Ésta es una receta suministrada por Castle Malting®. Tenga en cuenta que esta receta es solo una guía, lo cual le permite agregar su toque personal a su cerveza. No se puede garantizar que al seguirla se obtenga un resultado adecuado. Es posible que haya que realizar modificaciones para adaptarse a las características específicas de los ingredientes y a las condiciones tecnológicas específicas de la fábrica de cerveza.

Si desea más información o servicio, póngase en contacto con: info@castlemalting.com

Si desea más información o servicio, póngase en contacto con: info@castlemalting.com