Tu carrito

Tu carrito está vacío

Noticias de Empresa

Catálogos

Nuestras maltas

-

CHÂTEAU PALE ALE NATURE (MALTA ORGÁNICA)

Añadir al carrito

CHÂTEAU PALE ALE NATURE (MALTA ORGÁNICA)

Añadir al carrito

-

CHÂTEAU CARA GOLD NATURE® (MALTA ORGÁNICA)

Añadir al carrito

CHÂTEAU CARA GOLD NATURE® (MALTA ORGÁNICA)

Añadir al carrito

-

CHÂTEAU PILSEN NATURE® (MALTA ORGÁNICA)

Añadir al carrito

CHÂTEAU PILSEN NATURE® (MALTA ORGÁNICA)

Añadir al carrito

-

CHÂTEAU BLACK NATURE® (MALTA ORGÁNICA)

Añadir al carrito

CHÂTEAU BLACK NATURE® (MALTA ORGÁNICA)

Añadir al carrito

-

CHÂTEAU SPECIAL Belgium NATURE (MALTA ORGÁNICA)

Añadir al carrito

CHÂTEAU SPECIAL Belgium NATURE (MALTA ORGÁNICA)

Añadir al carrito

New Hops

Nuestras levaduras

Nuestras especias

Beer recipe - Scotch Beer

| ABV 4.5% | Color 32 EBC | Bitterness 18 IBU |

Description

Overwhelmingly malty, with a rich and dominant sweet malt flavor and aroma. Imparts a soft bitterness, roasted coffee aroma with pronounced smoked peat flavor. Strong color, a stable, fine, and colorful foam.

Overwhelmingly malty, with a rich and dominant sweet malt flavor and aroma. Imparts a soft bitterness, roasted coffee aroma with pronounced smoked peat flavor. Strong color, a stable, fine, and colorful foam.

Service:

Glass: Tulip Glass

Temperature: 4 - 8°C

Glass: Tulip Glass

Temperature: 4 - 8°C

BREWER`S TIPS

Play with the percentage of Chateau Peated to have more or less smoky flavors.

Play with the percentage of Chateau Peated to have more or less smoky flavors.

RECIPE FOR 100L

MALT

| Château Pilsen 2RS | 77% / 11.9 kg |

| Château Roasted Barley | 2% / 0.3 kg |

| Château Wheat Blanc | 7% / 1.0 kg |

| Château Peated | 5% / 0.8 kg |

| Château Cara Ruby® | 10% / 1.6 kg |

HOPS

| Goldings (6.0% aa) | 15.3 IBU / 100 g |

| Fuggle (4.5% aa) | 2.7 IBU / 100 g |

YEAST

| SafAle S-33 | 70 g |

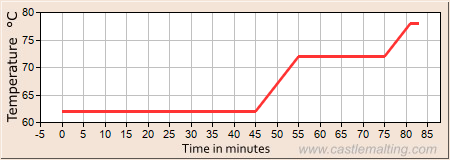

Mashing temperature

Step 1: Mashing

Mash-in and follow the profile below:

Mash-in and follow the profile below:

| pH | 5.3 | Mix Ratio | 3.0 L/kg |

Mash-in at 62°C

Rest for 45min at 62°C

Rise to 72°C at 1°C/min

Rest for 20min at 72°C and do the Iodine Test

Rise to 78°C at 1°C/min

Rest for 2min at 78°C to mash out

Once the mash is done, filter and sparge with water at 78°C

Rest for 45min at 62°C

Rise to 72°C at 1°C/min

Rest for 20min at 72°C and do the Iodine Test

Rise to 78°C at 1°C/min

Rest for 2min at 78°C to mash out

Once the mash is done, filter and sparge with water at 78°C

Step 2: Boiling

Boil for 60min.

Hop addition 1: After 10min add Goldings.

Hop Addition 2: After 50min add Fuggles.

Whirlpool to remove the trub

Boil for 60min.

Hop addition 1: After 10min add Goldings.

Hop Addition 2: After 50min add Fuggles.

Whirlpool to remove the trub

| Total evap 6.0% | Batch size 100L | OG 10.8oP | Efficiency 90% |

Step 3: Fermentation and Maturation

Cooldown the wort to 16°C and pitch the yeast.

Ferment at 16°C for 2 days then rise to 18°C. Once the fermentation is done (FG reached and off-flavors removed – about 7 days), drop the temperature to 8°C and rest for 1 day, and then harvest the yeast. Drop the temperature to 2°C and rest for 7 days.

Cooldown the wort to 16°C and pitch the yeast.

Ferment at 16°C for 2 days then rise to 18°C. Once the fermentation is done (FG reached and off-flavors removed – about 7 days), drop the temperature to 8°C and rest for 1 day, and then harvest the yeast. Drop the temperature to 2°C and rest for 7 days.

| Attenuation | 78% | FG | 2.4oP |

Step 4: Cold Aging and Packaging

Cold age the beer at -1°C for 5 days, remove the residual yeast, and carbonate until 2.4 volumes of CO2. The beer is ready to package and drink. Enjoy!

*For refermentation in the bottle, add brewing sugar and SafAle F-2.

Cold age the beer at -1°C for 5 days, remove the residual yeast, and carbonate until 2.4 volumes of CO2. The beer is ready to package and drink. Enjoy!

*For refermentation in the bottle, add brewing sugar and SafAle F-2.

Ésta es una receta suministrada por Castle Malting®. Tenga en cuenta que esta receta es solo una guía, lo cual le permite agregar su toque personal a su cerveza. No se puede garantizar que al seguirla se obtenga un resultado adecuado. Es posible que haya que realizar modificaciones para adaptarse a las características específicas de los ingredientes y a las condiciones tecnológicas específicas de la fábrica de cerveza.

Si desea más información o servicio, póngase en contacto con: info@castlemalting.com

Si desea más información o servicio, póngase en contacto con: info@castlemalting.com