Your cart

Your cart is empty

Company News

Our Malts

New Hops

Our Yeasts

Our Spices

Beer recipe - Belgian Blond Ale

| ABV 7.0% | Color 22 EBC | Bitterness* 28 IBU |

Description

Recipe for a typical Belgian Blond Ale. Golden coloured beer, slightly malty, with light caramel notes and high complexity brought by the Belgian yeast. During fermentation, the yeast shows all its power: moderate-high extract attenuation and high production of aromas, such as fruity esters and spicy phenolics, typical of a Belgian blond. During the tasting, this beer has a dry finish, always asking for another sip.

Recipe for a typical Belgian Blond Ale. Golden coloured beer, slightly malty, with light caramel notes and high complexity brought by the Belgian yeast. During fermentation, the yeast shows all its power: moderate-high extract attenuation and high production of aromas, such as fruity esters and spicy phenolics, typical of a Belgian blond. During the tasting, this beer has a dry finish, always asking for another sip.

*The bitterness depends on the alpha acid content of hops, boiling conditions and other parameters.

RECIPE FOR 100L

MALT

| Château Pilsen 2RS | 79.0% / 20.7 kg |

| Château Abbey® | 15.0% / 3.9 kg |

| Château Cara Blond® | 5.0% / 1.3 kg |

| Château Special Belgium® | 1.0% / 0.3 kg |

HOPS

| Magnum (12.0% AA) | 75 g |

| Styrian Golding (4.0% AA) | 75 g |

| Hallertau Mittelfruh (4.5% AA) | 75 g |

YEAST

| SafAle T-58 | 80 g |

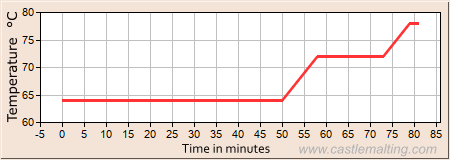

Mashing temperature

Step 1: Mashing

Mash-in and follow the profile below:

Mash-in and follow the profile below:

| pH | 5.3 | Mix Ratio | 2.5 L/kg |

Mash-in at 64°C.

Rest for 50min at 64°C.

Rise to 72°C at 1°C/min.

Rest for 15min at 72°C and do the Iodine Test.

Rise to 78°C at 1°C/min.

Rest for 2min at 78°C to mash out.

Once the mash is done, filter and sparge with water at 78°C

Rest for 50min at 64°C.

Rise to 72°C at 1°C/min.

Rest for 15min at 72°C and do the Iodine Test.

Rise to 78°C at 1°C/min.

Rest for 2min at 78°C to mash out.

Once the mash is done, filter and sparge with water at 78°C

Step 2: Boiling

Boil for 75min. Hop addition 1: After 15min add Nugget.

Hop Addition 2: After 70min add Styrian Golding and H Mittelfruh.

Whirlpool to remove the trub

Boil for 75min. Hop addition 1: After 15min add Nugget.

Hop Addition 2: After 70min add Styrian Golding and H Mittelfruh.

Whirlpool to remove the trub

| Total evap | 7.5% | Batch size | 100L | OG | 15.3oP | Efficiency | 80% |

Step 3: Fermentation and Maturation

Cool down the wort to 18°C and pitch the yeast.

Ferment at 18°C for 2 days then rise to 22°C. Once the fermentation is done (FG reached and off flavours removed – about 7 days), drop the temperature to 8°C and rest for 1 day and then harvest the yeast. Drop the temperature to 2°C and rest for 10 days.

Cool down the wort to 18°C and pitch the yeast.

Ferment at 18°C for 2 days then rise to 22°C. Once the fermentation is done (FG reached and off flavours removed – about 7 days), drop the temperature to 8°C and rest for 1 day and then harvest the yeast. Drop the temperature to 2°C and rest for 10 days.

| Attenuation | 80% | FG | 3.00oP |

Step 4: Cold Aging and Packaging

Cold age the beer at -1°C for 5 days, remove the residual yeast, and carbonate until 5.1 g/L of CO2. The beer is ready for packaging and drinking. Enjoy!

*For refermentation in the bottle, add brewing sugar and SafAle F-2.

*For refermentation in the bottle, add brewing sugar and SafAle F-2.

This recipe is provided by Castle Malting®. Please note that this recipe is just a guideline. Some modification might need to be done to meet different technologies, efficiencies and ingredients yield as grain dry extract and hop alpha acid percentage.

For further information & service please contact: info@castlemalting.com

Brewing is an experiment! Brew your own beer!

Send us your recipe, and we’ll be pleased to publish it on our website

For further information & service please contact: info@castlemalting.com

Brewing is an experiment! Brew your own beer!

Send us your recipe, and we’ll be pleased to publish it on our website