Your cart

Your cart is empty

Company News

Our Malts

New Hops

Our Yeasts

Our Spices

Beer recipe - Dunkel Bock

| ABV 6.2% | Color 60 EBC | Bitterness 25 IBU |

Description

Typical Dunkel Bock with Vienna and Munich malts to give a good and rich malty character and a small addition of roasted malt for color adjustment. Long boil to enhance the Maillard notes and addition of only one noble hop to promote a moderate bitterness to balance the full body of this beer.

Typical Dunkel Bock with Vienna and Munich malts to give a good and rich malty character and a small addition of roasted malt for color adjustment. Long boil to enhance the Maillard notes and addition of only one noble hop to promote a moderate bitterness to balance the full body of this beer.

Service:

Temperature: 4-6°C

Temperature: 4-6°C

BREWER`S TIPS

Mashing: Do the first amylolytic rest around 66-68°C to promote a full-body beer as part of this style. Keep the carbonation low to medium as part of the style.

Mashing: Do the first amylolytic rest around 66-68°C to promote a full-body beer as part of this style. Keep the carbonation low to medium as part of the style.

RECIPE FOR 100L

MALT

| Château Pilsen 2RS | 28% / 6.2 kg |

| Château Vienna | 30% / 6.6 kg |

| Château Munich | 38% / 8.4 kg |

| Château Black | 4% / 0.9 kg |

HOPS

| Hallertau Tradition (5.5% aa) | 200 g |

YEAST

| SafLager W-34/70 | 100 g |

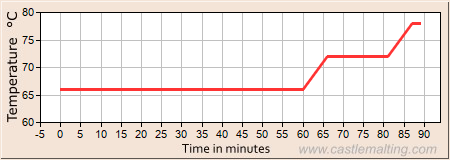

Mashing temperature

Step 1: Mashing

Mash-in and follow the profile below:

Mash-in and follow the profile below:

| pH | 5.3 | Mix Ratio | 2.7 L/kg |

Mash-in at 66°C

Rest for 60min at 66°C

Rise to 72°C at 1°C/min

Rest for 15min at 72°C and do the Iodine Test

Rise to 78°C at 1°C/min

Rest for 2min at 78°C to mash out

Once the mash is done, filter and sparge with water at 78°C

Rest for 60min at 66°C

Rise to 72°C at 1°C/min

Rest for 15min at 72°C and do the Iodine Test

Rise to 78°C at 1°C/min

Rest for 2min at 78°C to mash out

Once the mash is done, filter and sparge with water at 78°C

Step 2: Boiling

Boil for 90min.

Hop addition 1: After 30min add 130g of H. Tradition (22.5 IBU)

Hop Addition 2: After 80min add 70g H. Tradition (2.5 IBU)

Whirlpool to remove the trub

Boil for 90min.

Hop addition 1: After 30min add 130g of H. Tradition (22.5 IBU)

Hop Addition 2: After 80min add 70g H. Tradition (2.5 IBU)

Whirlpool to remove the trub

| Total evap | 9.0% | Batch size | 100L | OG | 14.0oP | Efficiency | 85% |

Step 3: Fermentation and Maturation

Cool down the wort to 12°C and pitch the yeast.

Ferment at 12°C for 2 days then rise to 15°C. Once the fermentation is done (FG reached and off-flavors removed – about 7 days), drop the temperature to 8°C and rest for 1 day, and then harvest the yeast. Drop the temperature to 2°C and rest for 10 days.

| Attenuation | 80% | FG | 2.95oP |

Step 4: Cold Aging and Packaging

Cold age the beer at 0°C for 5 days, remove the residual yeast, and carbonate until 2.4 volumes of CO2. The beer is ready to package and drink. Enjoy!

*For refermentation in the bottle, add brewing sugar and SafAle F-2.

Cold age the beer at 0°C for 5 days, remove the residual yeast, and carbonate until 2.4 volumes of CO2. The beer is ready to package and drink. Enjoy!

*For refermentation in the bottle, add brewing sugar and SafAle F-2.

This recipe is provided by Castle Malting®. Please note that this recipe is just a guideline. Some modification might need to be done to meet different technologies, efficiencies and ingredients yield as grain dry extract and hop alpha acid percentage.

For further information & service please contact: info@castlemalting.com

Brewing is an experiment! Brew your own beer!

Send us your recipe, and we’ll be pleased to publish it on our website

For further information & service please contact: info@castlemalting.com

Brewing is an experiment! Brew your own beer!

Send us your recipe, and we’ll be pleased to publish it on our website